steel fiber manufacturer

A Company You Can Trust:Tangshan YiAn metal products co., Ltd is a professional manufacturer of steel fiber. We have more than 10 years of experience in this field and have a good reputation in this field. Our products have won praise from customers worldwide.Quality and Safety:We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Our products have attained some certifications.Your Success, Our Glory:Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

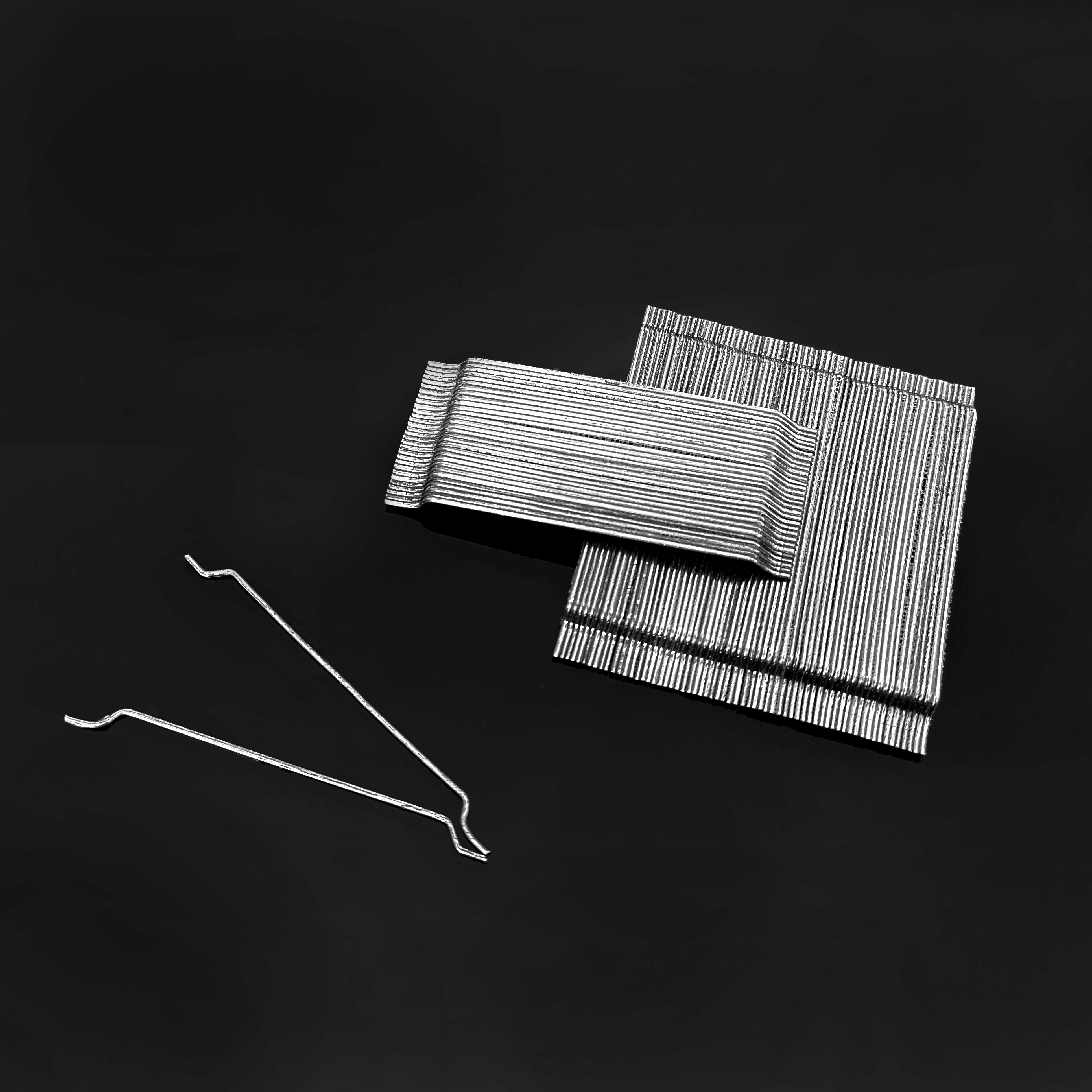

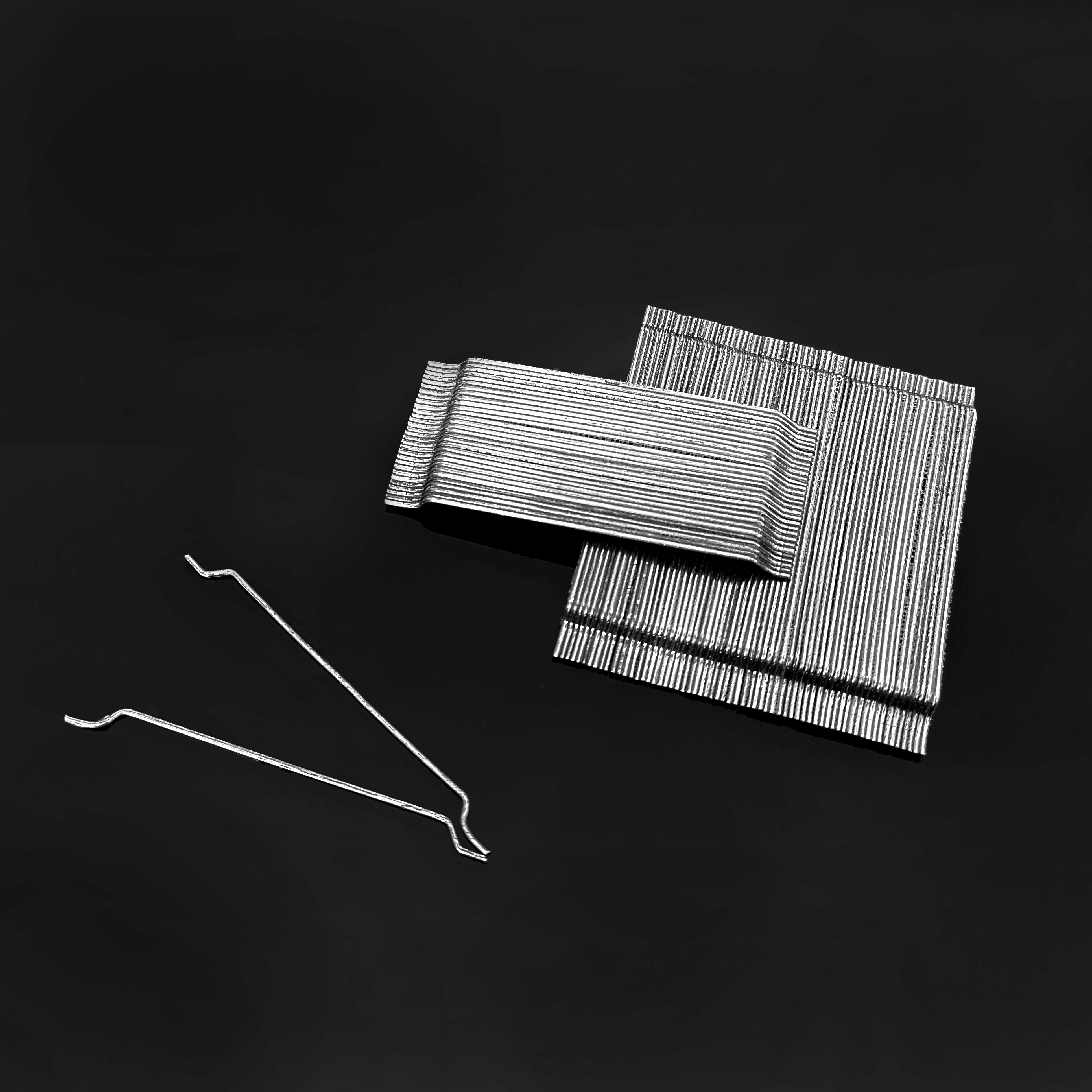

| Product name | steel fiber manufacturer |

| Keyword | high strength micro steel fiber,concrete steel fiber,glued type steel fiber manufacturers,steel fiber concrete,china steel fiber wire suppliers |

| Place of Origin | China |

| Diameter | 0.8MM |

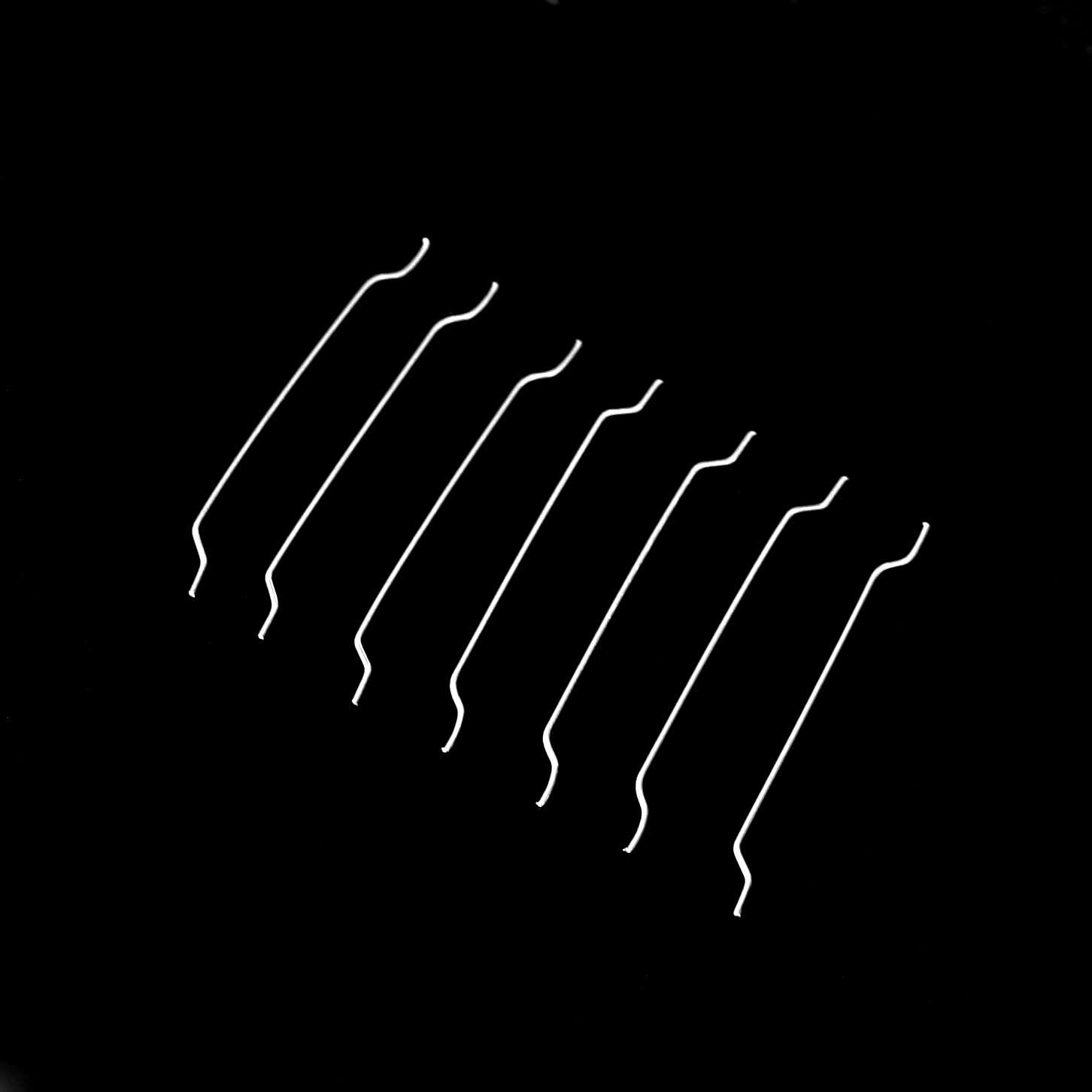

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Norway,Chile,Holy See (Vatican City),Ukraine,Tanzania,Kyrgyzstan |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

| Feature | Excellent Tensile |

FAQ Guide

Let’s continue!

2.How does steel fiber manufacturer impact the overall strength of concrete?

3.What is the difference between steel fiber and other types of concrete reinforcement?

4.How does steel fiber manufacturer impact the curing process of concrete?

5.Can steel fiber replace traditional reinforcement in concrete?

1.Is steel fiber suitable for use in high-stress applications?

Yes, steel fiber is suitable for use in high-stress applications. Steel fibers are known for their high tensile strength and durability, making them ideal for use in applications where high stress and heavy loads are present. They are commonly used in reinforced concrete structures, such as bridges, tunnels, and industrial floors, to improve their strength and resistance to cracking and fatigue. Steel fibers are also used in shotcrete and precast concrete applications, as well as in soil stabilization and reinforcement projects. Overall, steel fibers are a reliable and effective reinforcement material for high-stress applications.

2.How does steel fiber manufacturer impact the overall strength of concrete?

Steel fibers are small, thin strands of steel that are added to concrete mixtures to improve its strength and durability. When mixed with concrete, steel fibers act as reinforcement, providing additional tensile strength and improving the overall performance of the concrete.

The addition of steel fibers to concrete can significantly increase its strength and impact resistance. This is because the fibers act as a reinforcement, distributing the load and preventing cracks from forming. The fibers also help to hold the concrete together, making it more resistant to cracking and spalling.

The overall strength of concrete is determined by its compressive strength and its tensile strength. Compressive strength refers to the ability of concrete to withstand compression or being pushed together, while tensile strength refers to its ability to resist tension or being pulled apart. Steel fibers improve both of these properties, making the concrete stronger and more durable.

In addition to improving strength, steel fibers also help to control shrinkage and reduce cracking in concrete. This is because the fibers act as a barrier, preventing the formation of large cracks and limiting their propagation.

Overall, the addition of steel fibers to concrete can significantly increase its strength and durability, making it suitable for a wide range of applications, including industrial floors, pavements, and precast elements. However, the amount and type of steel fibers used must be carefully selected to ensure optimal performance and avoid any negative effects on the concrete.

3.What is the difference between steel fiber and other types of concrete reinforcement?

Steel fiber is a type of concrete reinforcement that is made from small, thin strands of steel. These fibers are added to the concrete mix to increase its strength and durability. Other types of concrete reinforcement include rebar, wire mesh, and synthetic fibers.

The main difference between steel fiber and other types of reinforcement is the material used. Steel fiber is made from steel, while rebar and wire mesh are made from metal rods or wires. Synthetic fibers, on the other hand, are made from materials such as polypropylene or nylon.

Another difference is the way in which they are added to the concrete mix. Steel fibers are typically added directly to the concrete mix during the mixing process, while rebar and wire mesh are placed in the formwork before the concrete is poured. Synthetic fibers can be added to the mix or placed in the formwork.

In terms of performance, steel fiber is known for its high tensile strength and ability to resist cracking and shrinkage in concrete. Rebar and wire mesh provide strength and reinforcement in specific areas of the concrete, while synthetic fibers can improve the overall durability and reduce cracking.

Overall, the choice of reinforcement will depend on the specific needs and requirements of the project. Steel fiber is often used in industrial and heavy-duty applications, while other types of reinforcement may be more suitable for residential or smaller projects.

4.How does steel fiber manufacturer impact the curing process of concrete?

Steel fibers can impact the curing process of concrete in several ways:

1. Accelerated curing: The presence of steel fibers in concrete can accelerate the curing process by increasing the rate of hydration. This is because the fibers provide a larger surface area for the cement to react with water, leading to faster strength development.

2. Reduced shrinkage: Steel fibers can help reduce the shrinkage of concrete during the curing process. This is because the fibers act as reinforcement, holding the concrete together and preventing cracks from forming due to shrinkage.

3. Improved strength: The addition of steel fibers can improve the overall strength of concrete, especially in the early stages of curing. This is because the fibers act as reinforcement, providing additional tensile strength to the concrete.

4. Increased workability: Steel fibers can improve the workability of concrete, making it easier to handle and place during the curing process. This is because the fibers act as a lubricant, reducing friction between the concrete particles and making it easier to mix and place.

5. Enhanced durability: The presence of steel fibers can improve the durability of concrete by reducing the risk of cracking and increasing its resistance to impact and abrasion. This is especially beneficial in high-stress environments such as industrial floors and pavements.

Overall, the addition of steel fibers can have a positive impact on the curing process of concrete, leading to faster strength development, reduced shrinkage, improved workability, and enhanced durability. However, it is important to carefully consider the type and dosage of fibers to avoid any negative effects on the concrete's properties.

5.Can steel fiber replace traditional reinforcement in concrete?

Steel fiber can be used as a replacement for traditional reinforcement in certain applications, but it is not a complete replacement. Traditional reinforcement, such as steel bars or mesh, is still necessary for structural integrity and to resist tensile forces in concrete. Steel fiber can be added to concrete to improve its strength, durability, and crack resistance, but it cannot completely replace traditional reinforcement. Additionally, the use of steel fiber in concrete requires careful design and testing to ensure its effectiveness and compatibility with the specific project requirements.