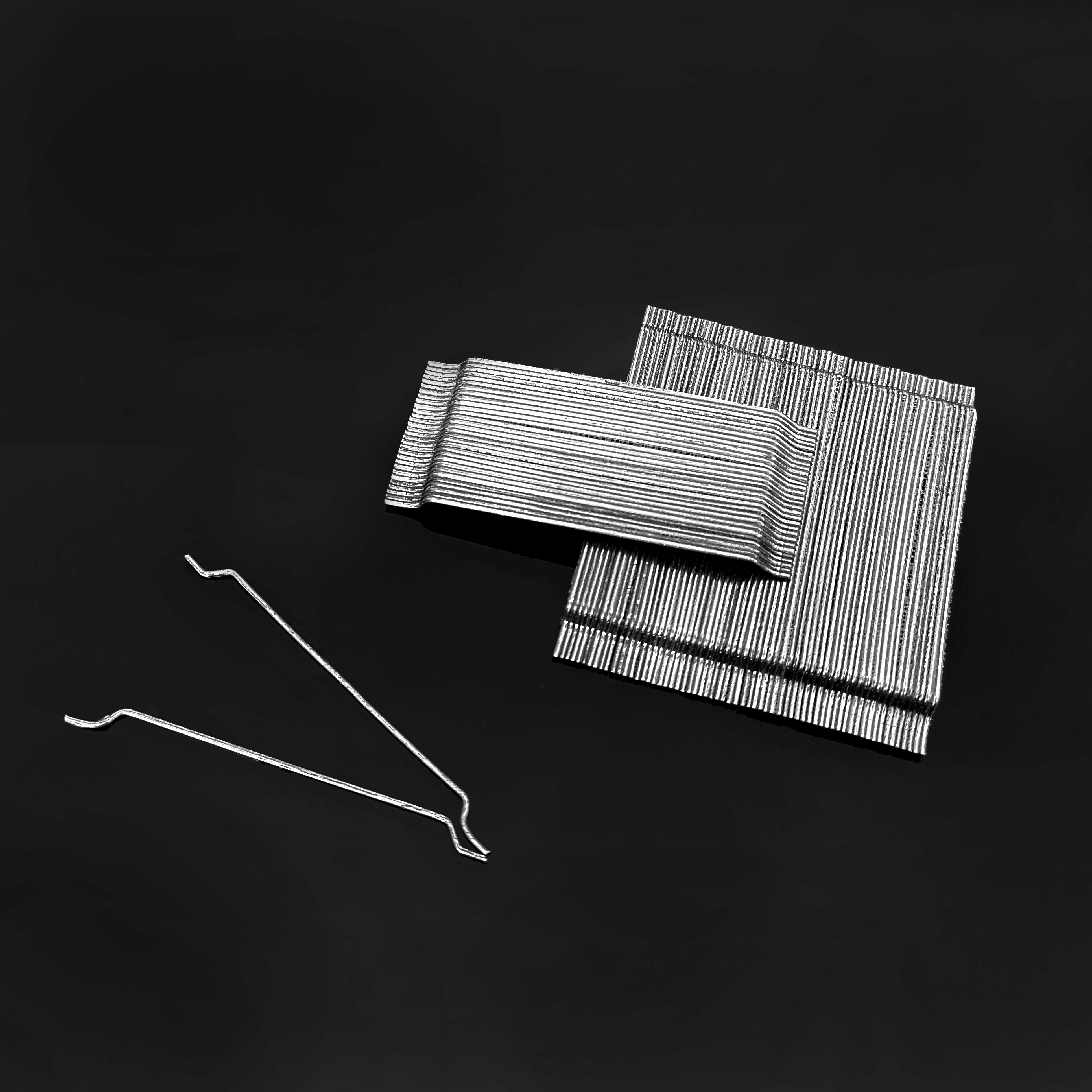

steel fiber mesh

Tangshan YiAn metal products co., Ltd.,Limited is a manufacturer of micro steel fiber,steel fiber reinforced composite,steel fiber reinforced concret,glued steel fiber manufacturers with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in the Tunneling, etc. and other industries. Our products are widely recognized and trusted by users ,Our products sold throughout China and exported to Southeast Asia, Europe,South Africa,Bhutan,Poland,Holy See (Vatican City),Djibouti, and other regions get the acceptance and high praise from our customers, The company has passed the ISO9001 international quality management system certification, can meet continuously changing economic and social needs.The company insists on the service for clients" spirit of enterprise. The company takes the good faith as the objective

| Product name | steel fiber mesh |

| Keyword | micro steel fiber,steel fiber reinforced composite,steel fiber reinforced concret,glued steel fiber manufacturers |

| Place of Origin | China |

| Diameter | 0.65MM |

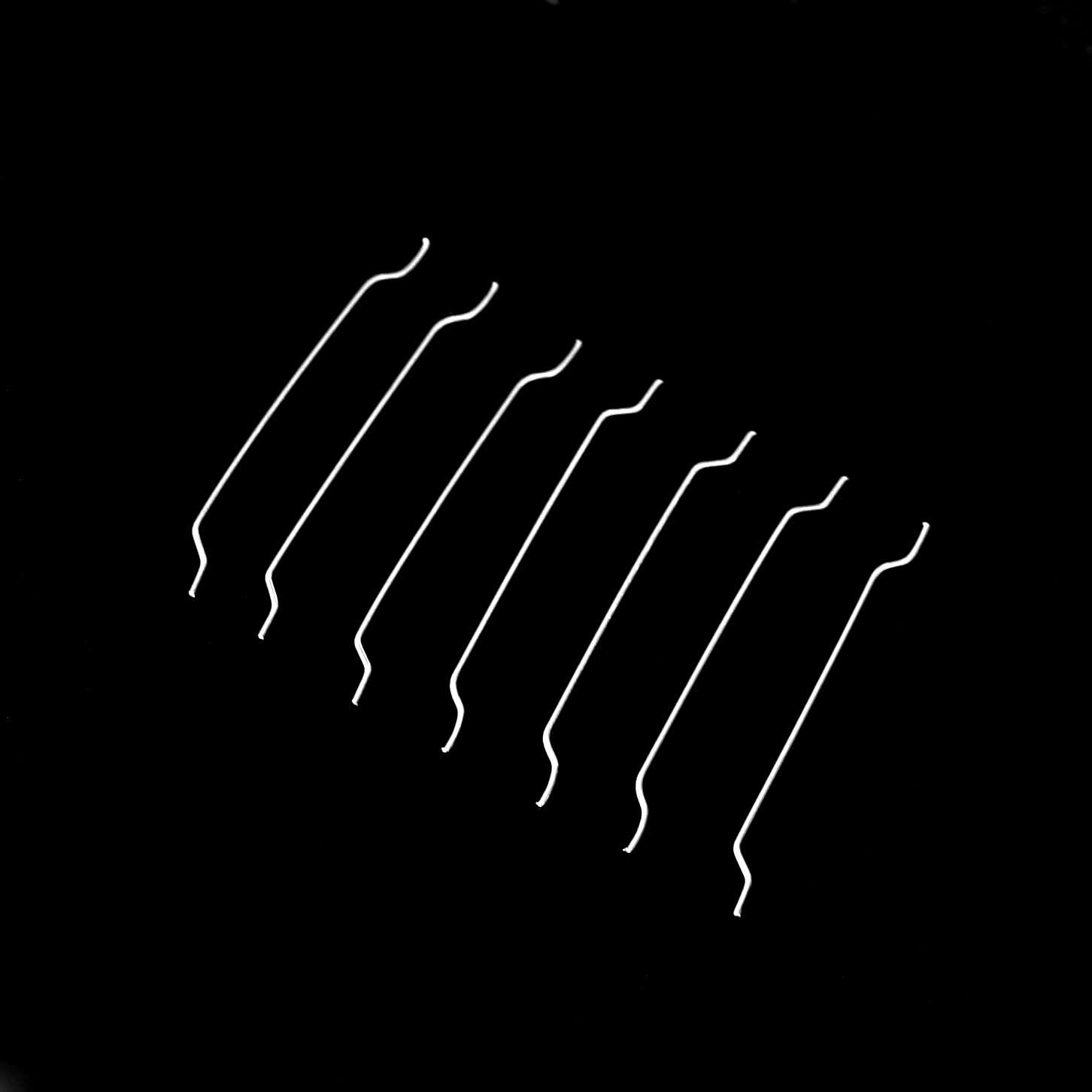

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:South Africa,Bhutan,Poland,Holy See (Vatican City),Djibouti |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

| Feature | Excellent Tensile |

FAQ Guide

Let’s continue!

2.Can steel fiber mesh reduce the overall weight of concrete structures?

3.How does the shape of steel fiber affect its performance in concrete?

4.What is the cost-effectiveness of using steel fiber in concrete construction?

5.What is the lifespan of concrete reinforced with steel fiber mesh?

1.Can steel fiber improve the flexural strength of concrete beams?

Yes, steel fiber can improve the flexural strength of concrete beams. Steel fibers are added to concrete to increase its tensile strength and improve its resistance to cracking and failure under bending or flexural loads. The addition of steel fibers can increase the flexural strength of concrete beams by up to 20-30%. This is because the steel fibers act as reinforcement, distributing the load more evenly and preventing cracks from propagating. Additionally, steel fibers can also improve the ductility and toughness of concrete, making it more resistant to sudden impacts or dynamic loads.

2.Can steel fiber mesh reduce the overall weight of concrete structures?

Yes, steel fiber can reduce the overall weight of concrete structures. This is because steel fibers are lightweight and can be added to the concrete mix in small quantities, reducing the amount of traditional reinforcement needed. This results in a lighter and more efficient concrete structure. Additionally, steel fibers can also improve the strength and durability of the concrete, allowing for thinner and lighter sections to be used. This can lead to cost savings in materials and transportation, as well as reduced environmental impact.

3.How does the shape of steel fiber affect its performance in concrete?

The shape of steel fiber can affect its performance in concrete in several ways:

1. Bonding: The shape of steel fiber can affect its ability to bond with the concrete matrix. Fibers with a smooth surface and a circular or elliptical cross-section tend to have better bonding with the concrete, resulting in improved load transfer between the fiber and the matrix.

2. Distribution: The shape of steel fiber can also affect its distribution within the concrete mix. Fibers with a flat or hook-like shape tend to clump together, leading to uneven distribution and potential weak spots in the concrete. On the other hand, fibers with a more uniform shape, such as a straight or crimped shape, can disperse more evenly throughout the mix, resulting in a more uniform reinforcement.

3. Orientation: The shape of steel fiber can also affect its orientation within the concrete. Fibers with a flat or hook-like shape may have a tendency to align themselves parallel to the surface of the concrete, which can reduce their effectiveness in providing reinforcement in all directions. On the other hand, fibers with a more uniform shape can be more easily dispersed and oriented in multiple directions, providing better overall reinforcement.

4. Crack control: The shape of steel fiber can also affect its ability to control cracking in concrete. Fibers with a flat or hook-like shape tend to be more effective in controlling shrinkage cracks, as they can bridge the cracks and distribute the stress more evenly. However, fibers with a more uniform shape can also provide good crack control by creating a three-dimensional reinforcement network within the concrete.

Overall, the shape of steel fiber can significantly impact its performance in concrete, and the selection of the appropriate shape should be based on the specific requirements and properties of the concrete mix.

4.What is the cost-effectiveness of using steel fiber in concrete construction?

The cost-effectiveness of using steel fiber in concrete construction depends on various factors such as the type and quality of steel fiber, the type of concrete mix, and the specific project requirements. In general, using steel fiber in concrete construction can increase the initial cost of the project due to the added cost of the fibers. However, it can also provide long-term cost savings by improving the durability and strength of the concrete, reducing the need for maintenance and repairs, and increasing the lifespan of the structure.

Studies have shown that the use of steel fiber in concrete can reduce the overall construction cost by up to 25% compared to traditional reinforcement methods. This is because steel fibers can replace traditional reinforcement materials such as rebar, reducing the labor and material costs associated with their installation. Additionally, the use of steel fiber can also reduce the construction time, leading to further cost savings.

Moreover, the use of steel fiber in concrete can also result in cost savings in terms of energy efficiency. The addition of steel fibers can improve the thermal and acoustic properties of concrete, reducing the need for additional insulation and soundproofing materials.

Overall, while the initial cost of using steel fiber in concrete construction may be higher, the long-term cost savings and benefits make it a cost-effective option in many cases. It is important to consider the specific project requirements and consult with a structural engineer to determine the most cost-effective solution for each project.

5.What is the lifespan of concrete reinforced with steel fiber mesh?

The lifespan of concrete reinforced with steel fiber can vary depending on various factors such as the quality of materials used, environmental conditions, and maintenance. However, on average, it is estimated that concrete reinforced with steel fiber can have a lifespan of 50-100 years.