steel fiber machine

A Company You Can Trust:Tangshan YiAn metal products co., Ltd is a professional manufacturer of steel fiber. We have more than 10 years of experience in this field and have a good reputation in this field. Our products have won praise from customers worldwide.Quality and Safety:We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Our products have attained some certifications.Your Success, Our Glory:Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

| Product name | steel fiber machine |

| Keyword | helix steel fiber,concrete steel fiber,steel fiber cost,customized glued steel fiber |

| Place of Origin | China |

| Applicable Industries | Dam, etc. |

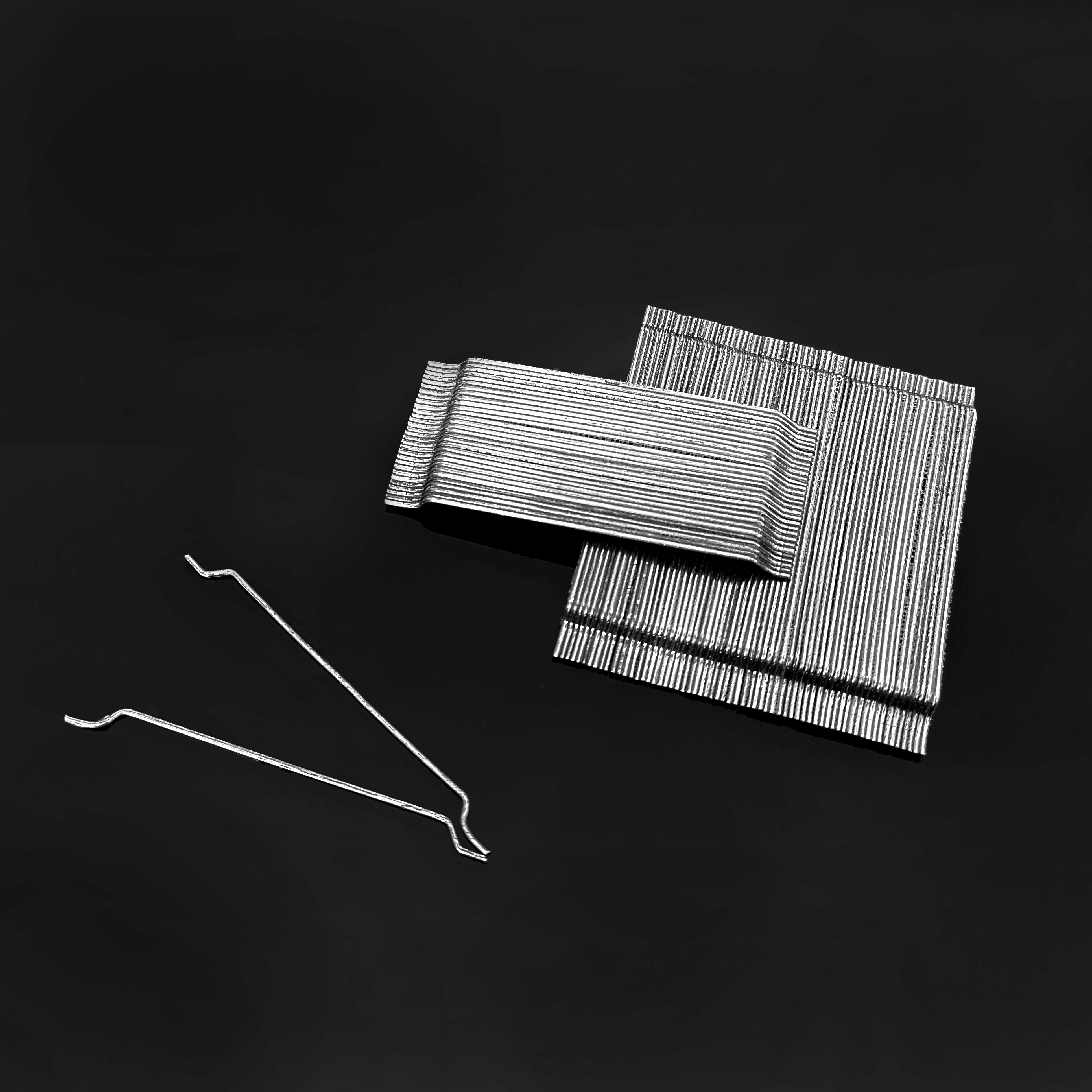

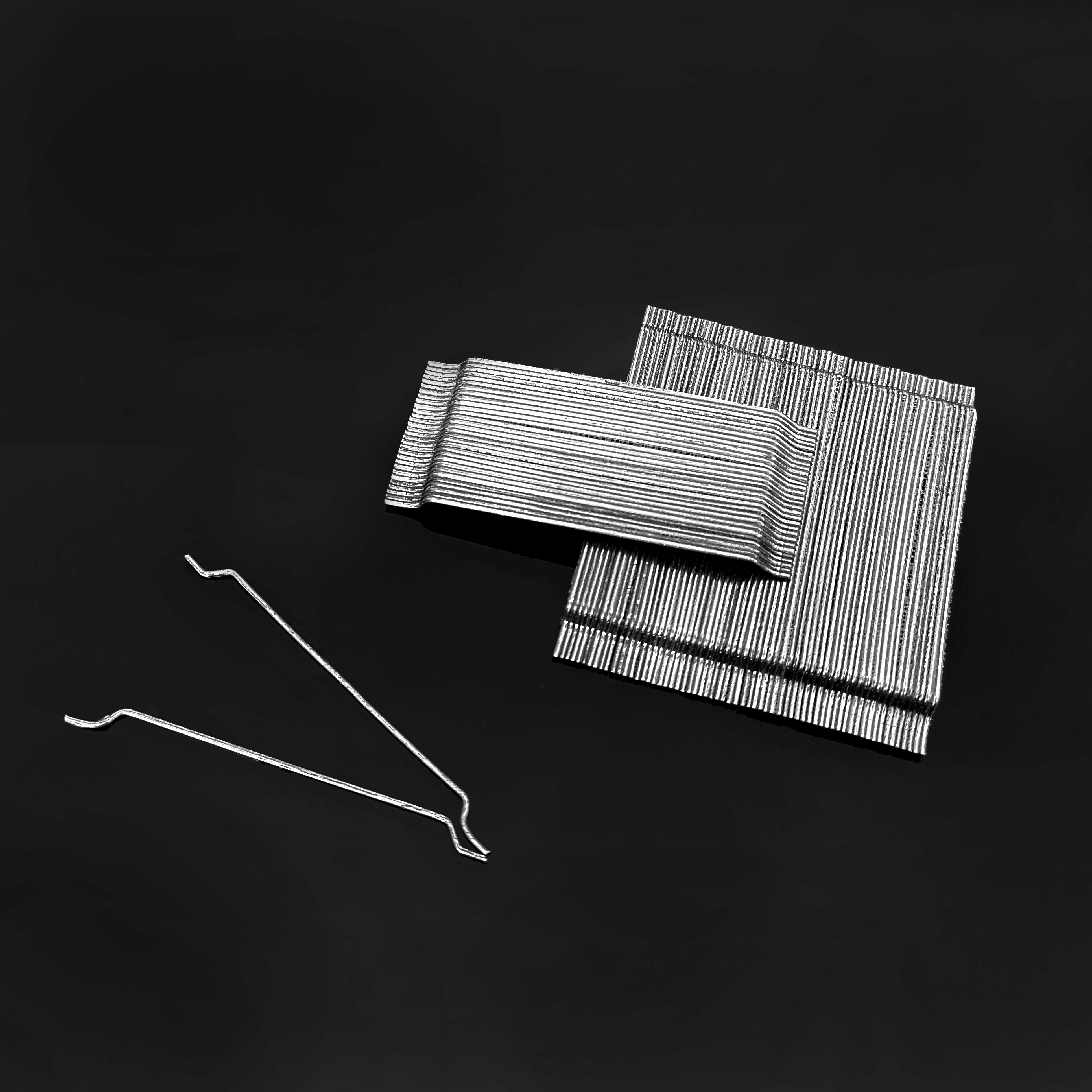

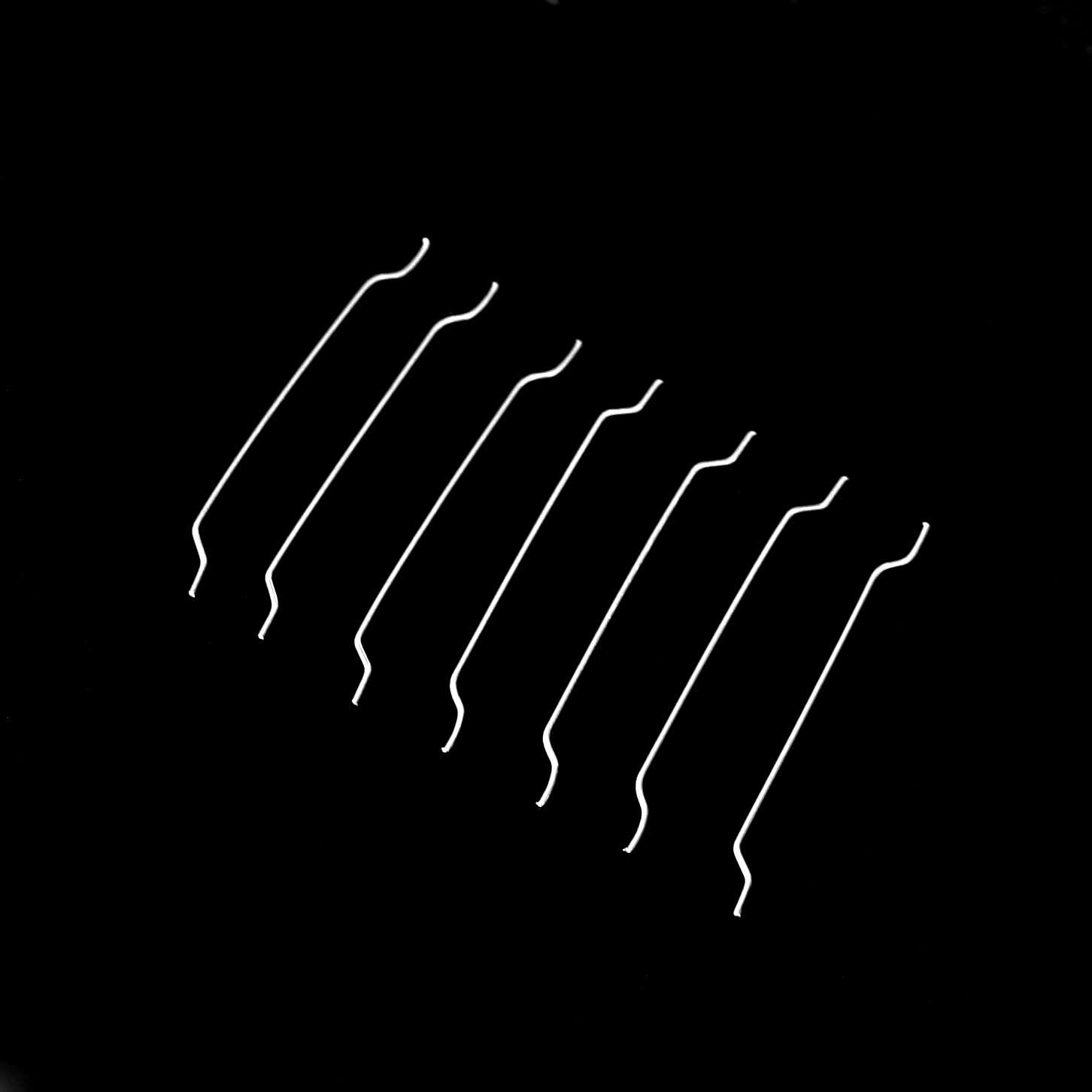

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Jersey,Tanzania,Croatia,Lesotho,Juan de Nova Island,Congo, Democratic Republic of the,Saint Helena,Europa Island |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

FAQ Guide

Let’s continue!

2.Can steel fiber be used in precast concrete elements?

3.Does steel fiber help prevent cracking in concrete?

4.What are the long-term maintenance requirements for concrete with steel fiber machine reinforcement?

5.What is the lifespan of concrete reinforced with steel fiber machine?

1.How does steel fiber machine impact the curing process of concrete?

Steel fibers can impact the curing process of concrete in several ways:

1. Accelerated curing: The presence of steel fibers in concrete can accelerate the curing process by increasing the rate of hydration. This is because the fibers provide a larger surface area for the cement to react with water, leading to faster strength development.

2. Reduced shrinkage: Steel fibers can help reduce the shrinkage of concrete during the curing process. This is because the fibers act as reinforcement, holding the concrete together and preventing cracks from forming due to shrinkage.

3. Improved strength: The addition of steel fibers can improve the overall strength of concrete, especially in the early stages of curing. This is because the fibers act as reinforcement, providing additional tensile strength to the concrete.

4. Increased workability: Steel fibers can improve the workability of concrete, making it easier to handle and place during the curing process. This is because the fibers act as a lubricant, reducing friction between the concrete particles and making it easier to mix and place.

5. Enhanced durability: The presence of steel fibers can improve the durability of concrete by reducing the risk of cracking and increasing its resistance to impact and abrasion. This is especially beneficial in high-stress environments such as industrial floors and pavements.

Overall, the addition of steel fibers can have a positive impact on the curing process of concrete, leading to faster strength development, reduced shrinkage, improved workability, and enhanced durability. However, it is important to carefully consider the type and dosage of fibers to avoid any negative effects on the concrete's properties.

2.Can steel fiber be used in precast concrete elements?

Yes, steel fiber can be used in precast concrete elements. Steel fiber is often added to precast concrete to improve its strength, durability, and crack resistance. It can also help reduce the amount of reinforcement needed in the precast element, making it more cost-effective. However, the use of steel fiber in precast concrete should be carefully considered and designed by a structural engineer to ensure proper placement and distribution of the fibers.

3.Does steel fiber help prevent cracking in concrete?

Yes, steel fiber can help prevent cracking in concrete. Steel fibers are added to concrete to improve its tensile strength and ductility, making it less prone to cracking. The fibers act as reinforcement, distributing stress and preventing cracks from forming. They also help to hold the concrete together if cracks do occur, reducing the likelihood of further damage. Additionally, steel fibers can improve the overall durability and longevity of concrete structures.

4.What are the long-term maintenance requirements for concrete with steel fiber machine reinforcement?

The long-term maintenance requirements for concrete with steel fiber reinforcement include regular inspections, repairs, and cleaning.

1. Regular Inspections: It is important to conduct regular inspections of the concrete structure to check for any signs of damage or deterioration. This can help identify any potential issues early on and prevent them from becoming more serious.

2. Repairs: If any cracks or damage are found during inspections, they should be repaired immediately to prevent further damage. The repair method will depend on the extent of the damage and may involve patching, sealing, or replacing the affected area.

3. Cleaning: Concrete with steel fiber reinforcement should be cleaned regularly to remove any dirt, debris, or other contaminants that can cause corrosion or deterioration of the steel fibers. This can be done using a pressure washer or by scrubbing with a mild detergent.

4. Corrosion Protection: Steel fibers can be susceptible to corrosion, especially in harsh environments. To prevent this, the concrete should be properly sealed and protected with a corrosion inhibitor.

5. Monitoring: It is important to monitor the performance of the concrete over time to ensure that it is still meeting the required strength and durability standards. This can be done through regular testing and evaluation.

6. Proper Use and Maintenance of Equipment: If the concrete structure is subjected to heavy loads or other stresses, it is important to use proper equipment and techniques to prevent damage to the steel fibers. This may include using rubber-tipped tools and avoiding excessive vibration.

Overall, the key to maintaining concrete with steel fiber reinforcement is to address any issues promptly and to follow proper construction and maintenance practices. This will help ensure the long-term durability and performance of the structure.

5.What is the lifespan of concrete reinforced with steel fiber machine?

The lifespan of concrete reinforced with steel fiber can vary depending on various factors such as the quality of materials used, environmental conditions, and maintenance. However, on average, it is estimated that concrete reinforced with steel fiber can have a lifespan of 50-100 years.