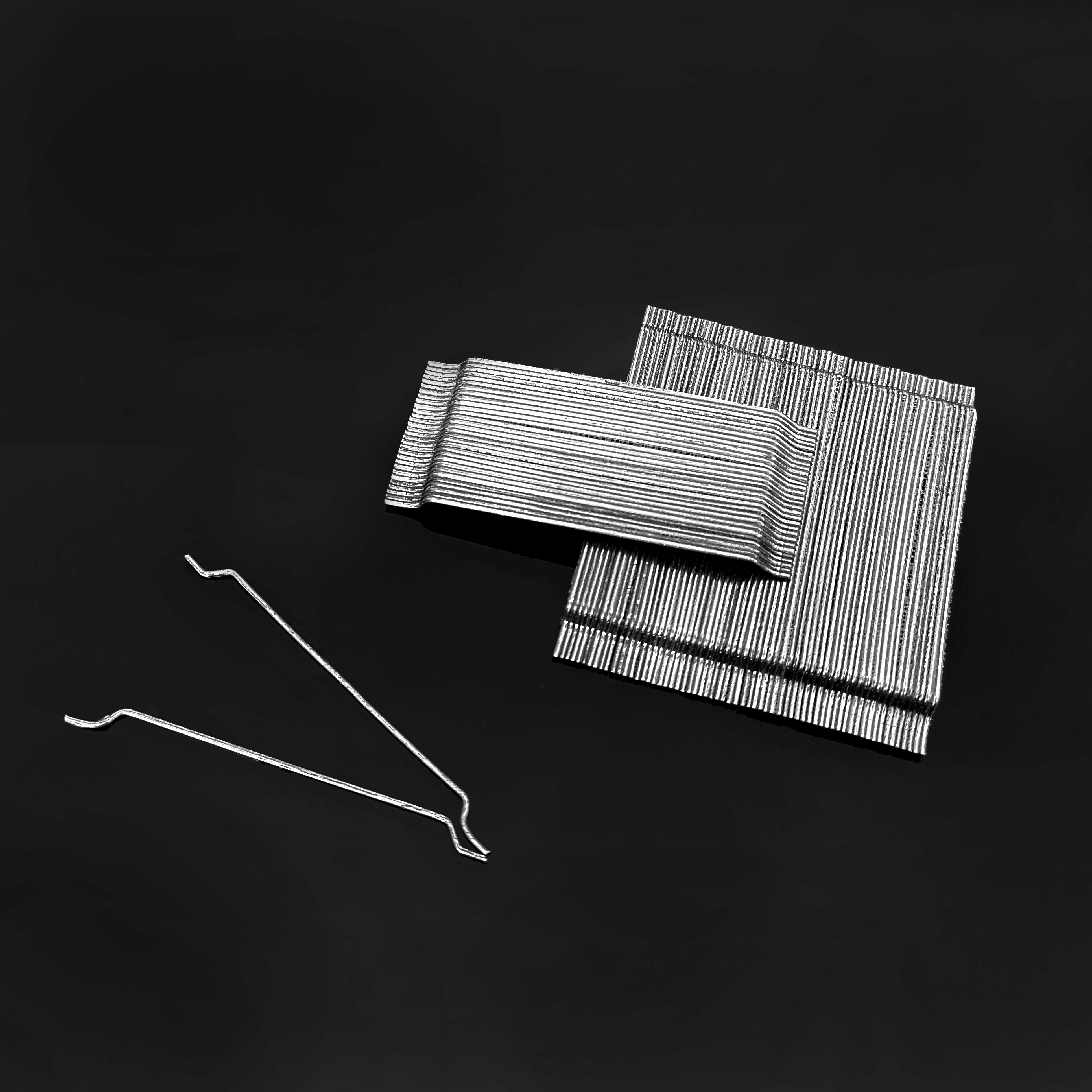

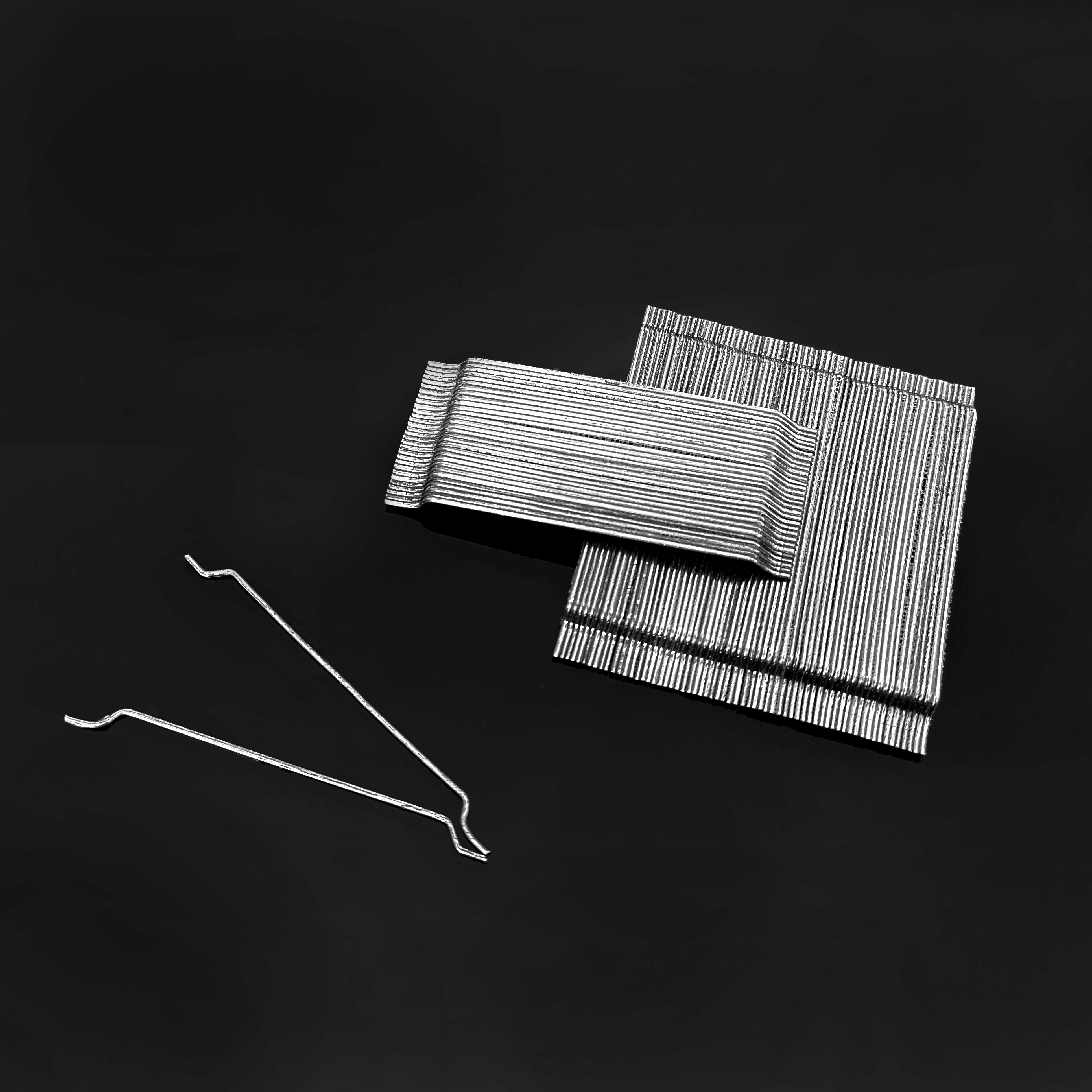

steel fiber i95

Tangshan YiAn metal products co., Ltd. locates in tangshan city, focusing on production of cold drawn steel wire steel fiber, loose hooked end steel fiber, glued steel fiber, stainless steel fiber, copper coated steel fiber & shear steel fibers, and our products has passed ISO9001 and CE certificate.

Our fiber are widely used in Concrete reinforcement/industrial floor And we have sold our fiber to more than 20 counties.

| Product name | steel fiber i95 |

| Keyword | straight steel fiber,steel fiber reinforced concret,dramix steel fiber,glued type steel fiber manufacturers |

| Place of Origin | China |

| Applicable Industries | Power Plant, etc. |

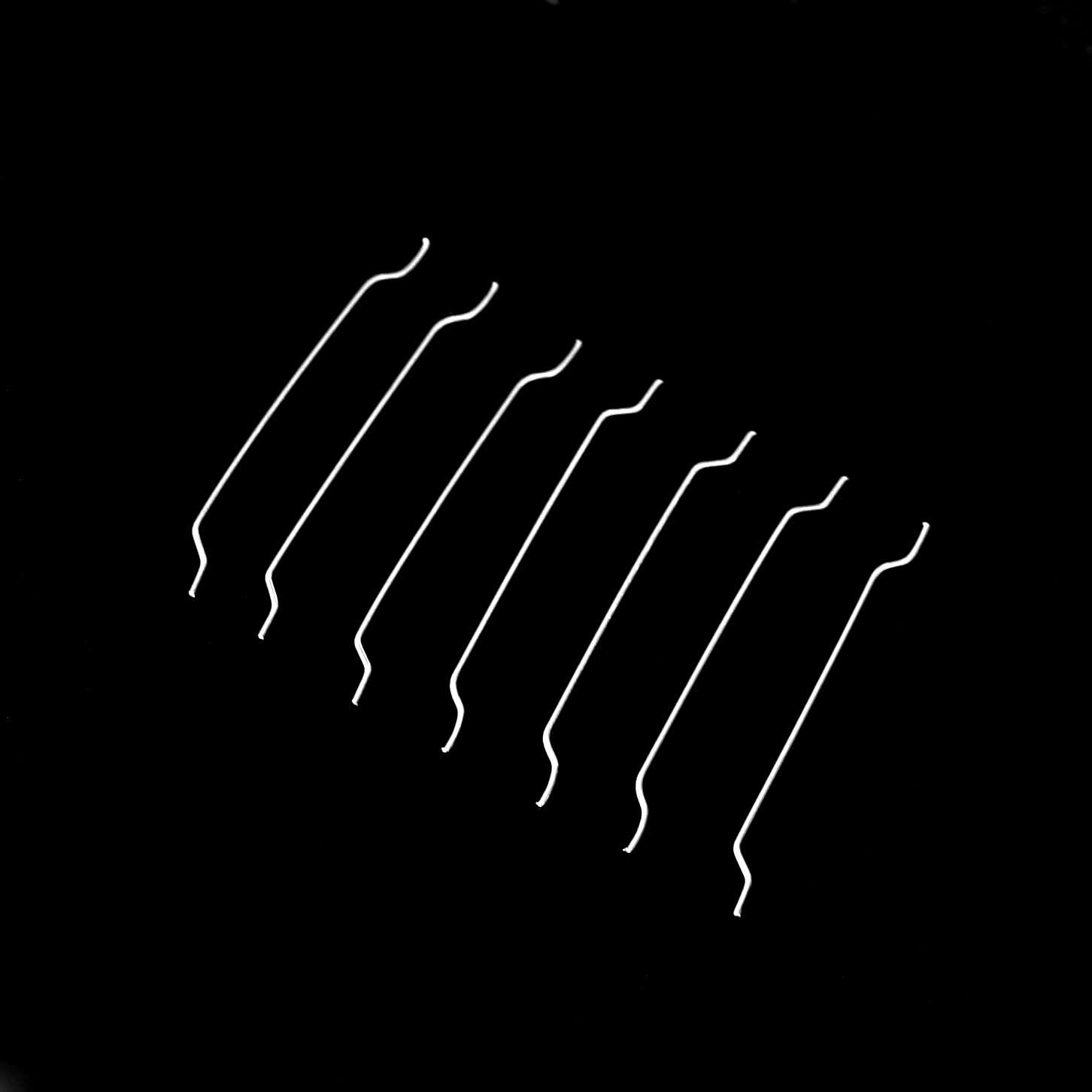

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Bulgaria,Jamaica,Norfolk Island,Gibraltar,Sierra Leone,Clipperton Island,Senegal,Poland,Tunisia |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

FAQ Guide

Let’s continue!

2.How does steel fiber strengthen concrete structures?

3.Are there any code requirements or guidelines for using steel fiber i95 in concrete?

4.How does steel fiber affect the durability of concrete?

1.What is the lifespan of concrete reinforced with steel fiber i95?

The lifespan of concrete reinforced with steel fiber can vary depending on various factors such as the quality of materials used, environmental conditions, and maintenance. However, on average, it is estimated that concrete reinforced with steel fiber can have a lifespan of 50-100 years.

2.How does steel fiber strengthen concrete structures?

Steel fibers are small, thin strands of steel that are added to concrete mixtures to increase its strength and durability. When mixed with concrete, these fibers are evenly distributed throughout the mixture, providing reinforcement and improving the overall performance of the concrete structure.

There are several ways in which steel fibers strengthen concrete structures:

1. Increased tensile strength: Concrete is strong in compression but weak in tension. Steel fibers act as tiny reinforcement bars, providing additional tensile strength to the concrete. This helps to prevent cracking and improve the overall structural integrity of the concrete.

2. Improved ductility: Steel fibers also improve the ductility of concrete, which is its ability to deform without breaking. This is important in structures that are subjected to heavy loads or seismic activity, as it allows the concrete to absorb energy and prevent sudden failure.

3. Crack control: The addition of steel fibers helps to control cracking in concrete structures. As the fibers are evenly distributed throughout the concrete, they help to distribute stress and prevent cracks from forming or spreading.

Overall, the addition of steel fibers to concrete mixtures can significantly improve the strength, durability, and performance of concrete structures, making them more reliable and long-lasting.

3.Are there any code requirements or guidelines for using steel fiber i95 in concrete?

Yes, there are several code requirements and guidelines for using steel fiber in concrete. These include:

1. ASTM C1116/C1116M - Standard Specification for Fiber-Reinforced Concrete and Shotcrete This standard provides requirements for the physical properties, testing, and acceptance criteria for steel fiber-reinforced concrete and shotcrete.

2. ACI 544.3R - Guide for Specifying, Proportioning, and Production of Fiber-Reinforced Concrete This guide provides recommendations for the design, proportioning, and production of fiber-reinforced concrete, including steel fiber-reinforced concrete.

3. ACI 544.4R - Design Guide for Steel Fiber-Reinforced Concrete This guide provides information on the design and construction of steel fiber-reinforced concrete structures, including material properties, mix design, and structural design considerations.

4. ACI 544.1R - State-of-the-Art Report on Fiber-Reinforced Concrete This report provides an overview of the current state of knowledge and practice for fiber-reinforced concrete, including steel fiber-reinforced concrete.

5. International Building Code (IBC) The IBC includes provisions for the use of fiber-reinforced concrete, including steel fiber-reinforced concrete, in building construction. These provisions cover material properties, design, and construction requirements.

6. National Building Code of Canada (NBCC) The NBCC includes requirements for the use of fiber-reinforced concrete, including steel fiber-reinforced concrete, in building construction. These requirements cover material properties, design, and construction requirements.

It is important to consult with local building codes and regulations, as well as the manufacturer's recommendations, when using steel fiber in concrete.

4.How does steel fiber affect the durability of concrete?

Steel fiber can have both positive and negative effects on the durability of concrete.

Positive effects:

1. Increased crack resistance: Steel fibers act as reinforcement in concrete, providing additional tensile strength and reducing the formation and propagation of cracks. This helps to improve the overall durability of the concrete by preventing the ingress of harmful substances such as water, chemicals, and gases.

2. Improved impact resistance: The addition of steel fibers can increase the impact resistance of concrete, making it more resistant to damage from heavy loads or impacts. This can help to extend the lifespan of the concrete and improve its durability.

3. Enhanced resistance to freeze-thaw cycles: Steel fibers can help to improve the durability of concrete in cold climates by reducing the damage caused by freeze-thaw cycles. The fibers act as reinforcement, preventing the formation of cracks and reducing the risk of spalling.

4. Reduced shrinkage and cracking: Steel fibers can help to reduce the shrinkage of concrete during the curing process, which can lead to fewer cracks and improved durability.

Negative effects:

1. Corrosion risk: If the steel fibers are not properly coated or protected, they can be susceptible to corrosion, which can weaken the concrete and reduce its durability.

2. Difficulty in mixing and placing: The addition of steel fibers can make the concrete mix more difficult to work with, as the fibers can clump together and create an uneven distribution. This can lead to a decrease in the strength and durability of the concrete.

3. Increased cost: The use of steel fibers can increase the cost of concrete, which may make it less economically feasible for some projects.

Overall, the addition of steel fibers can have a positive impact on the durability of concrete, but it is important to carefully consider the potential negative effects and take appropriate measures to mitigate them.