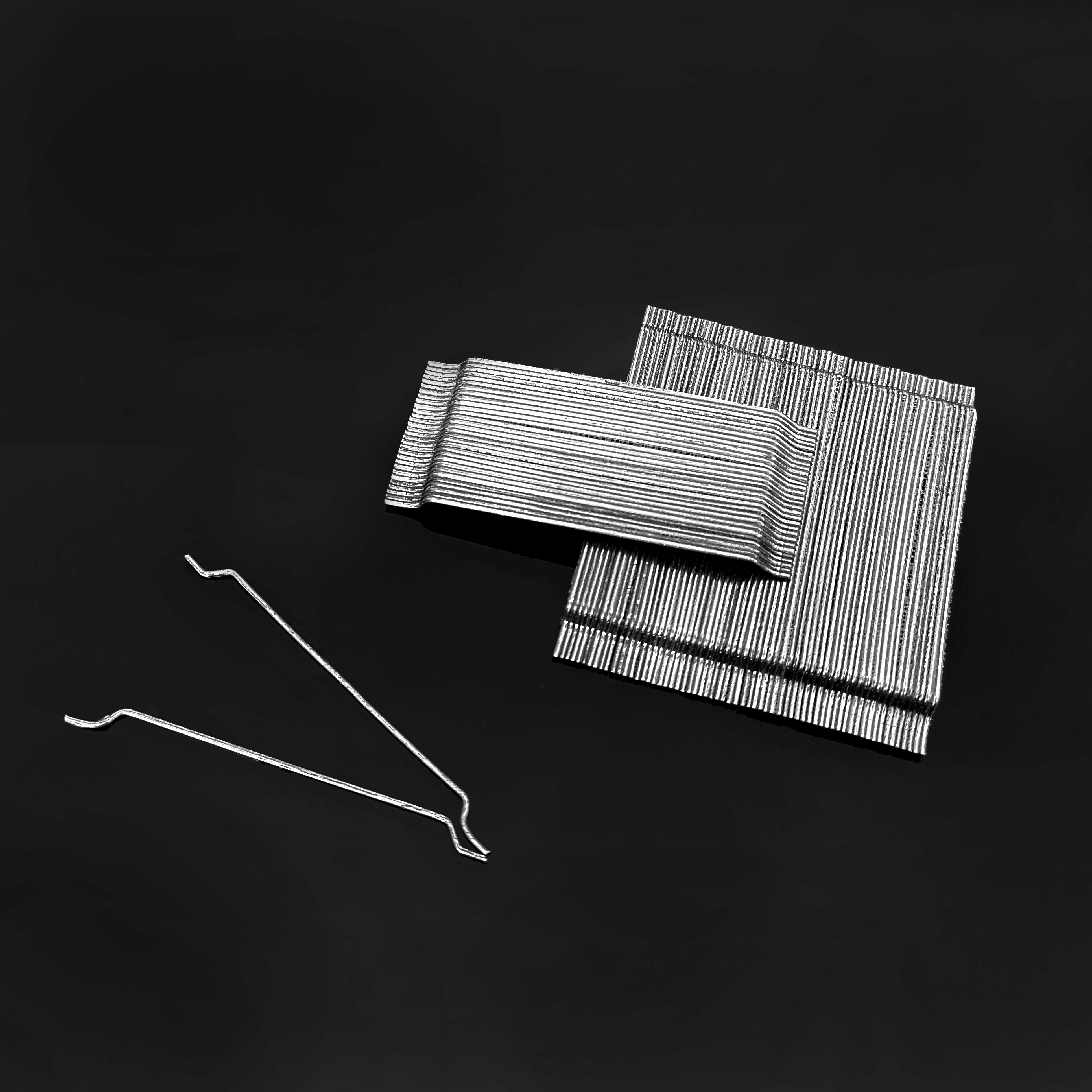

steel fiber i80

Tangshan YiAn metal products co., Ltd Our company plays a leading role in steel fiber industry, steel fiber types and specifications is comprehensive among Chinese manufacturer, including the Hooked Ends steel fiber, crimped steel fiber,steel fiber machine,steel fiber reinforced cement concrete,steel fiber on chroma.

Our company has achieved EC CERTIFICATE OF CONFORMITY in year 2006 and passed ISO9001 Quality System certification in year 2004. We passed strict testing supervised by National metallic quality supervise and testing centre.Our steel fiber has widely used in many important project such as rapid transit railway and etc, are well sold to more than 28 provinces/cities in China and exported to Germany, Norway, Estonia, United Kingdom,Micronesia, Federated States of,Fiji,Panama,Armenia,Angola,Guyana, Thailand, and Nepal and etc. We have won high reputations from all of our clients for our steel fiber and service.

| Product name | steel fiber i80 |

| Keyword | crimped steel fiber,steel fiber machine,steel fiber reinforced cement concrete,steel fiber on chroma |

| Place of Origin | China |

| Applicable Industries | rapid transit railway, etc. |

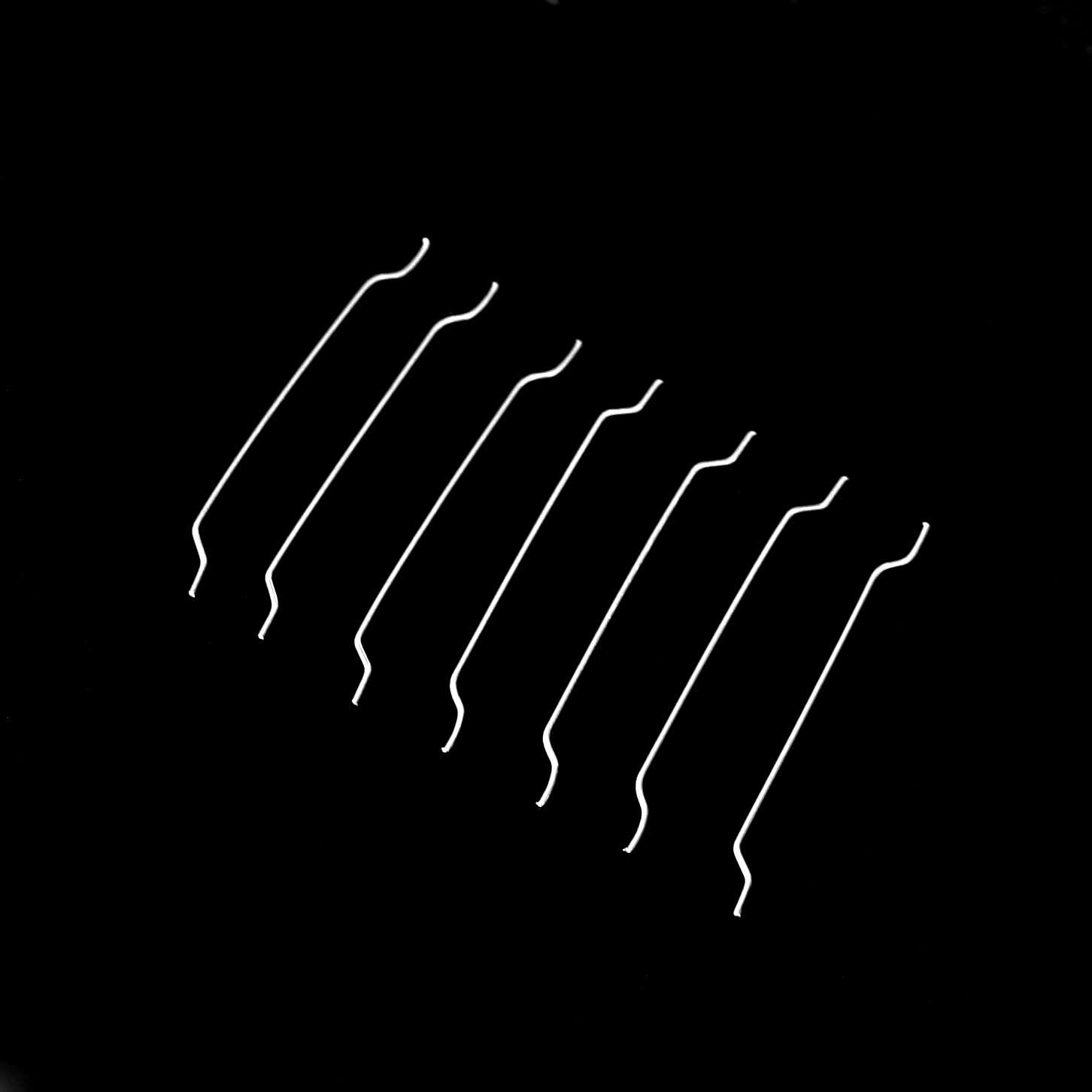

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:United Kingdom,Micronesia, Federated States of,Fiji,Panama,Armenia,Angola,Guyana |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

FAQ Guide

Let’s continue!

2.How does steel fiber i80 impact the curing process of concrete?

3.Can steel fiber i80 improve the impact resistance of concrete?

4.Is it necessary to use a specific type of concrete mix for steel fiber i80 reinforcement?

5.What is the lifespan of concrete reinforced with steel fiber i80?

1.What is the recommended spacing distance for steel fiber i80s in concrete?

The recommended spacing distance for steel fibers in concrete is typically between 1.5 to 2.5 inches (38 to 64 mm). However, this may vary depending on the specific application and type of steel fibers being used. It is important to consult with a structural engineer or follow the manufacturer's recommendations for the specific project.

2.How does steel fiber i80 impact the curing process of concrete?

Steel fibers can impact the curing process of concrete in several ways:

1. Accelerated curing: The presence of steel fibers in concrete can accelerate the curing process by increasing the rate of hydration. This is because the fibers provide a larger surface area for the cement to react with water, leading to faster strength development.

2. Reduced shrinkage: Steel fibers can help reduce the shrinkage of concrete during the curing process. This is because the fibers act as reinforcement, holding the concrete together and preventing cracks from forming due to shrinkage.

3. Improved strength: The addition of steel fibers can improve the overall strength of concrete, especially in the early stages of curing. This is because the fibers act as reinforcement, providing additional tensile strength to the concrete.

4. Increased workability: Steel fibers can improve the workability of concrete, making it easier to handle and place during the curing process. This is because the fibers act as a lubricant, reducing friction between the concrete particles and making it easier to mix and place.

5. Enhanced durability: The presence of steel fibers can improve the durability of concrete by reducing the risk of cracking and increasing its resistance to impact and abrasion. This is especially beneficial in high-stress environments such as industrial floors and pavements.

Overall, the addition of steel fibers can have a positive impact on the curing process of concrete, leading to faster strength development, reduced shrinkage, improved workability, and enhanced durability. However, it is important to carefully consider the type and dosage of fibers to avoid any negative effects on the concrete's properties.

3.Can steel fiber i80 improve the impact resistance of concrete?

Yes, steel fiber can improve the impact resistance of concrete. Steel fibers are added to concrete to increase its tensile strength and ductility, making it more resistant to cracking and breaking under impact. The fibers act as reinforcement, distributing the force of the impact throughout the concrete and preventing it from concentrating in one area. This results in a more durable and impact-resistant concrete. Additionally, steel fibers can also improve the energy absorption capacity of concrete, making it better able to withstand sudden impacts without significant damage.

4.Is it necessary to use a specific type of concrete mix for steel fiber i80 reinforcement?

Yes, it is necessary to use a specific type of concrete mix for steel fiber reinforcement. This is because the addition of steel fibers changes the properties and behavior of the concrete, and therefore requires a different mix design to ensure proper performance. The mix design for steel fiber reinforced concrete (SFRC) takes into account factors such as the type and amount of fibers, the desired strength and durability, and the placement and finishing methods. Using the correct mix design is crucial for achieving the desired strength, durability, and overall performance of the SFRC.

5.What is the lifespan of concrete reinforced with steel fiber i80?

The lifespan of concrete reinforced with steel fiber can vary depending on various factors such as the quality of materials used, environmental conditions, and maintenance. However, on average, it is estimated that concrete reinforced with steel fiber can have a lifespan of 50-100 years.