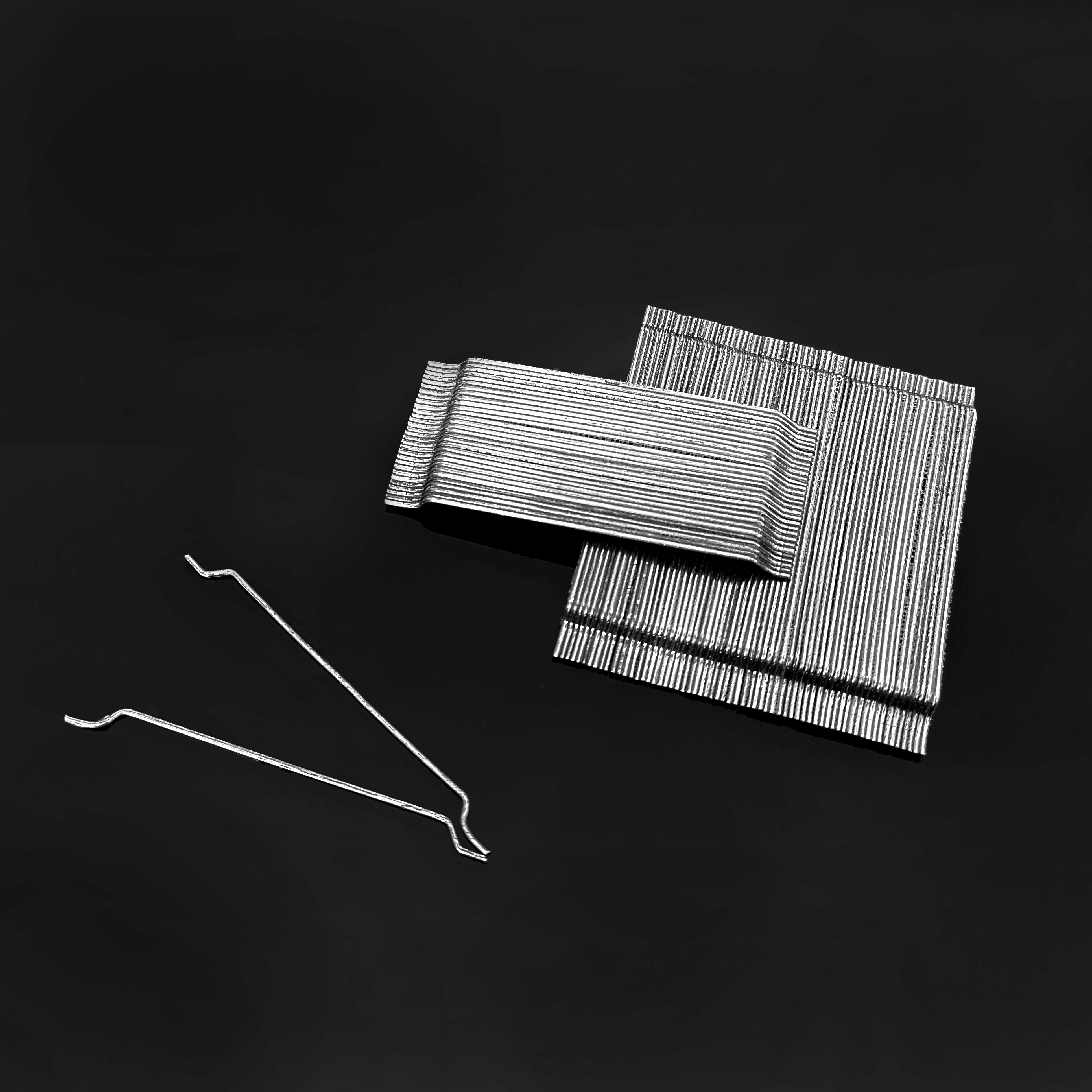

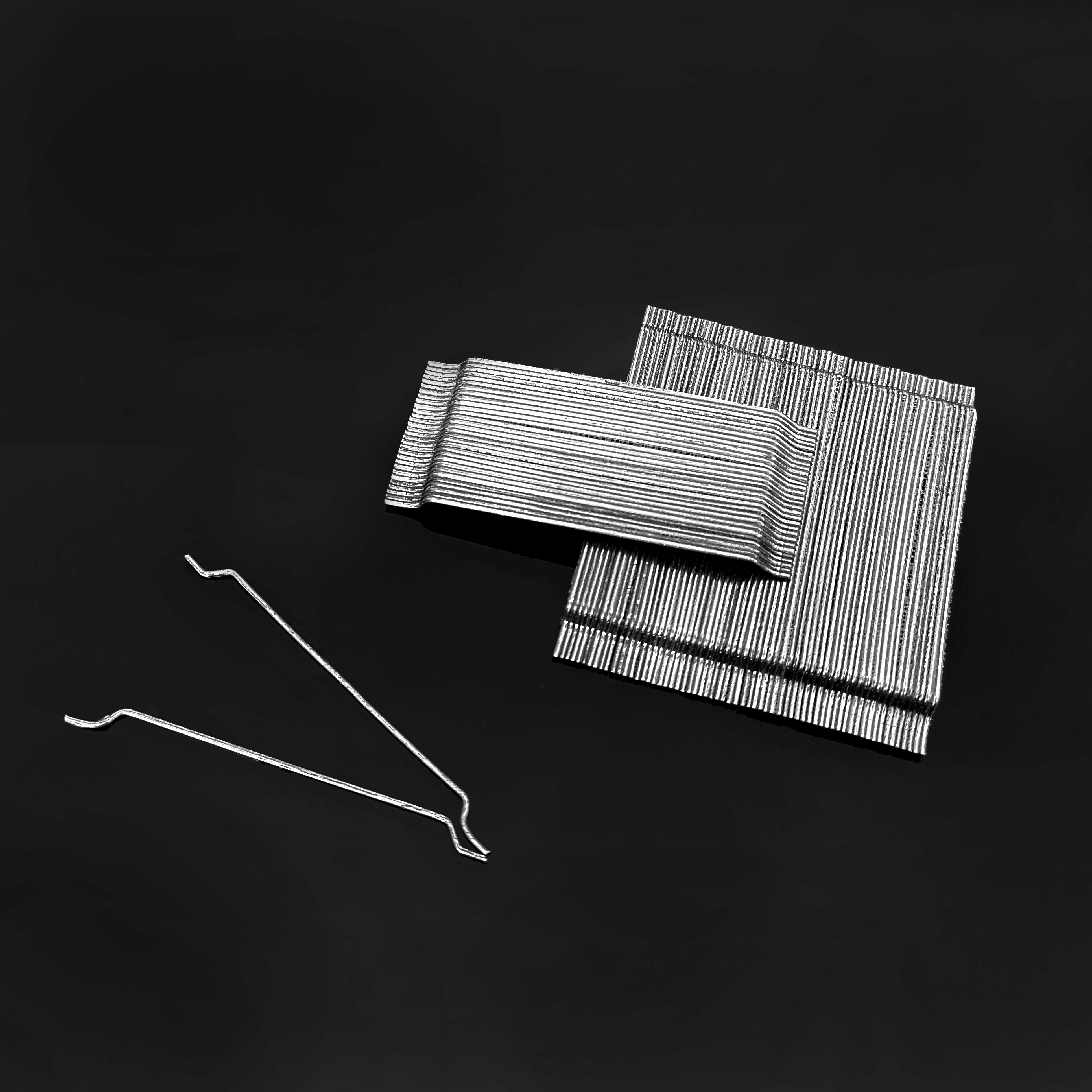

steel fiber i70

Tangshan YiAn metal products co., Ltd. is the only manufacturer that obtained patents for steel fiber inventions in China.Our company is specialized in R&D and production of stainless-steel fiber. Self-developed machines and new technologies are our core advantages in the field.

Our products include Melting heat-resistant stainless-steel fiber, steel fiber concrete reinforcement,steel fiber machine,hook end steel fiber,micro steel fiber.Our products are widely applied to refractory castable for industrial furnaces, concrete in road pavement, bridges, airport runways, tunnels, dams, harbors, and engineering of marine, explosion-resistant and earthquake-resistant, etc.

| Product name | steel fiber i70 |

| Keyword | steel fiber concrete reinforcement,steel fiber machine,hook end steel fiber,micro steel fiber |

| Place of Origin | China |

| Diameter | 0.95MM |

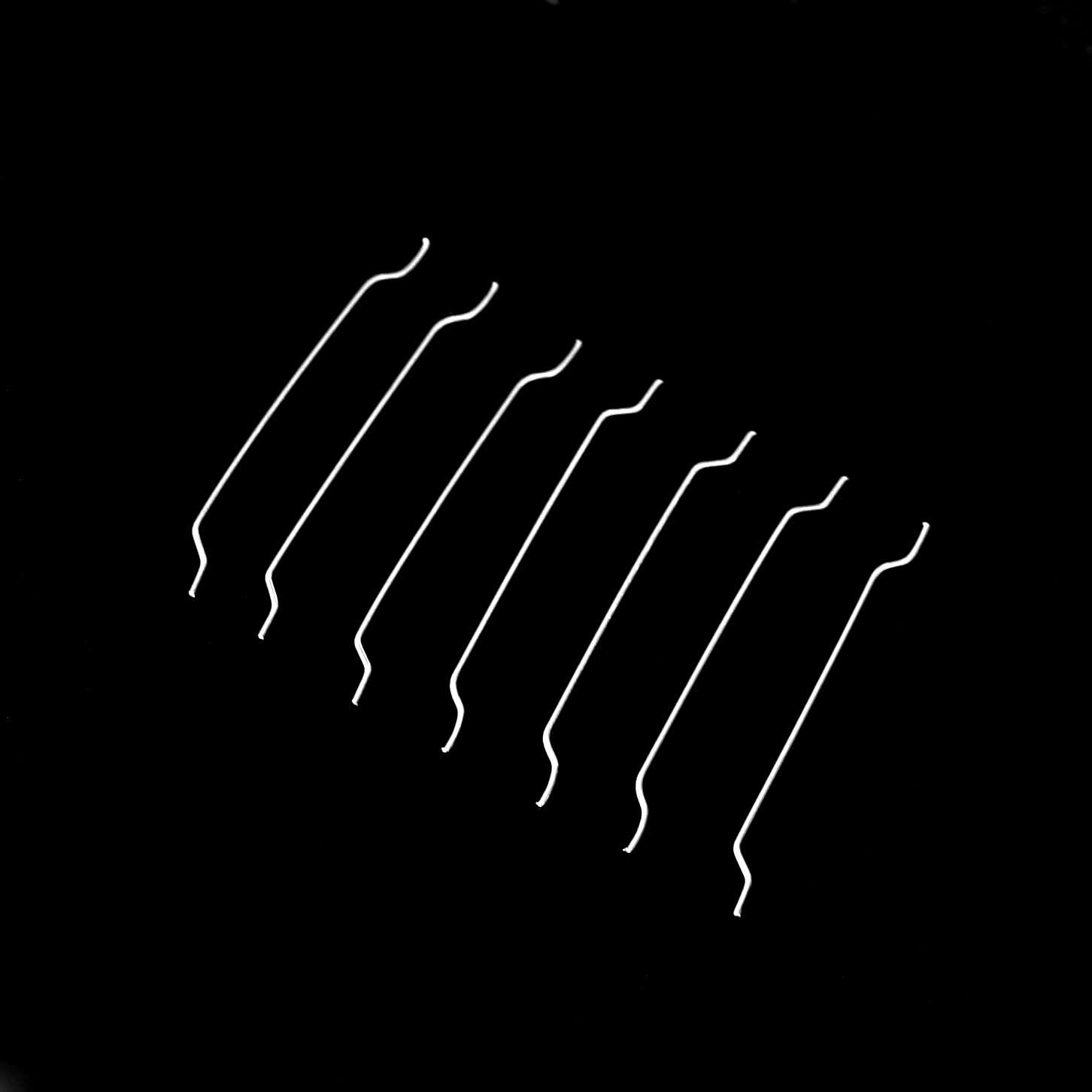

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Kuwait,Pakistan,Wallis and Futuna,Bolivia,Marshall Islands,Kyrgyzstan |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

| Feature | Excellent Tensile |

FAQ Guide

Let’s continue!

2.How does steel fiber affect the durability of concrete?

3.Can steel fiber i70 reduce the risk of spalling in concrete structures?

4.Is steel fiber suitable for use in high-stress applications?

5.Can steel fiber replace traditional reinforcement in concrete?

1.Can steel fiber i70 be recycled after its use in concrete?

Yes, steel fiber can be recycled after its use in concrete. The steel fibers can be extracted from the concrete using specialized equipment and then melted down to be used in the production of new steel products. This process helps to reduce the amount of waste generated from construction projects and promotes sustainability in the construction industry.

2.How does steel fiber affect the durability of concrete?

Steel fiber can have both positive and negative effects on the durability of concrete.

Positive effects:

1. Increased crack resistance: Steel fibers act as reinforcement in concrete, providing additional tensile strength and reducing the formation and propagation of cracks. This helps to improve the overall durability of the concrete by preventing the ingress of harmful substances such as water, chemicals, and gases.

2. Improved impact resistance: The addition of steel fibers can increase the impact resistance of concrete, making it more resistant to damage from heavy loads or impacts. This can help to extend the lifespan of the concrete and improve its durability.

3. Enhanced resistance to freeze-thaw cycles: Steel fibers can help to improve the durability of concrete in cold climates by reducing the damage caused by freeze-thaw cycles. The fibers act as reinforcement, preventing the formation of cracks and reducing the risk of spalling.

4. Reduced shrinkage and cracking: Steel fibers can help to reduce the shrinkage of concrete during the curing process, which can lead to fewer cracks and improved durability.

Negative effects:

1. Corrosion risk: If the steel fibers are not properly coated or protected, they can be susceptible to corrosion, which can weaken the concrete and reduce its durability.

2. Difficulty in mixing and placing: The addition of steel fibers can make the concrete mix more difficult to work with, as the fibers can clump together and create an uneven distribution. This can lead to a decrease in the strength and durability of the concrete.

3. Increased cost: The use of steel fibers can increase the cost of concrete, which may make it less economically feasible for some projects.

Overall, the addition of steel fibers can have a positive impact on the durability of concrete, but it is important to carefully consider the potential negative effects and take appropriate measures to mitigate them.

3.Can steel fiber i70 reduce the risk of spalling in concrete structures?

Yes, steel fiber can reduce the risk of spalling in concrete structures. Steel fibers are added to concrete mixtures to improve its strength, durability, and resistance to cracking. When used in high-stress areas, such as in concrete structures, steel fibers can help prevent spalling by providing additional reinforcement and reducing the formation of cracks. This helps to maintain the integrity of the concrete and prevent water and other harmful substances from penetrating and causing spalling. Additionally, steel fibers can also improve the bond between the concrete and any reinforcing steel, further reducing the risk of spalling.

4.Is steel fiber suitable for use in high-stress applications?

Yes, steel fiber is suitable for use in high-stress applications. Steel fibers are known for their high tensile strength and durability, making them ideal for use in applications where high stress and heavy loads are present. They are commonly used in reinforced concrete structures, such as bridges, tunnels, and industrial floors, to improve their strength and resistance to cracking and fatigue. Steel fibers are also used in shotcrete and precast concrete applications, as well as in soil stabilization and reinforcement projects. Overall, steel fibers are a reliable and effective reinforcement material for high-stress applications.

5.Can steel fiber replace traditional reinforcement in concrete?

Steel fiber can be used as a replacement for traditional reinforcement in certain applications, but it is not a complete replacement. Traditional reinforcement, such as steel bars or mesh, is still necessary for structural integrity and to resist tensile forces in concrete. Steel fiber can be added to concrete to improve its strength, durability, and crack resistance, but it cannot completely replace traditional reinforcement. Additionally, the use of steel fiber in concrete requires careful design and testing to ensure its effectiveness and compatibility with the specific project requirements.