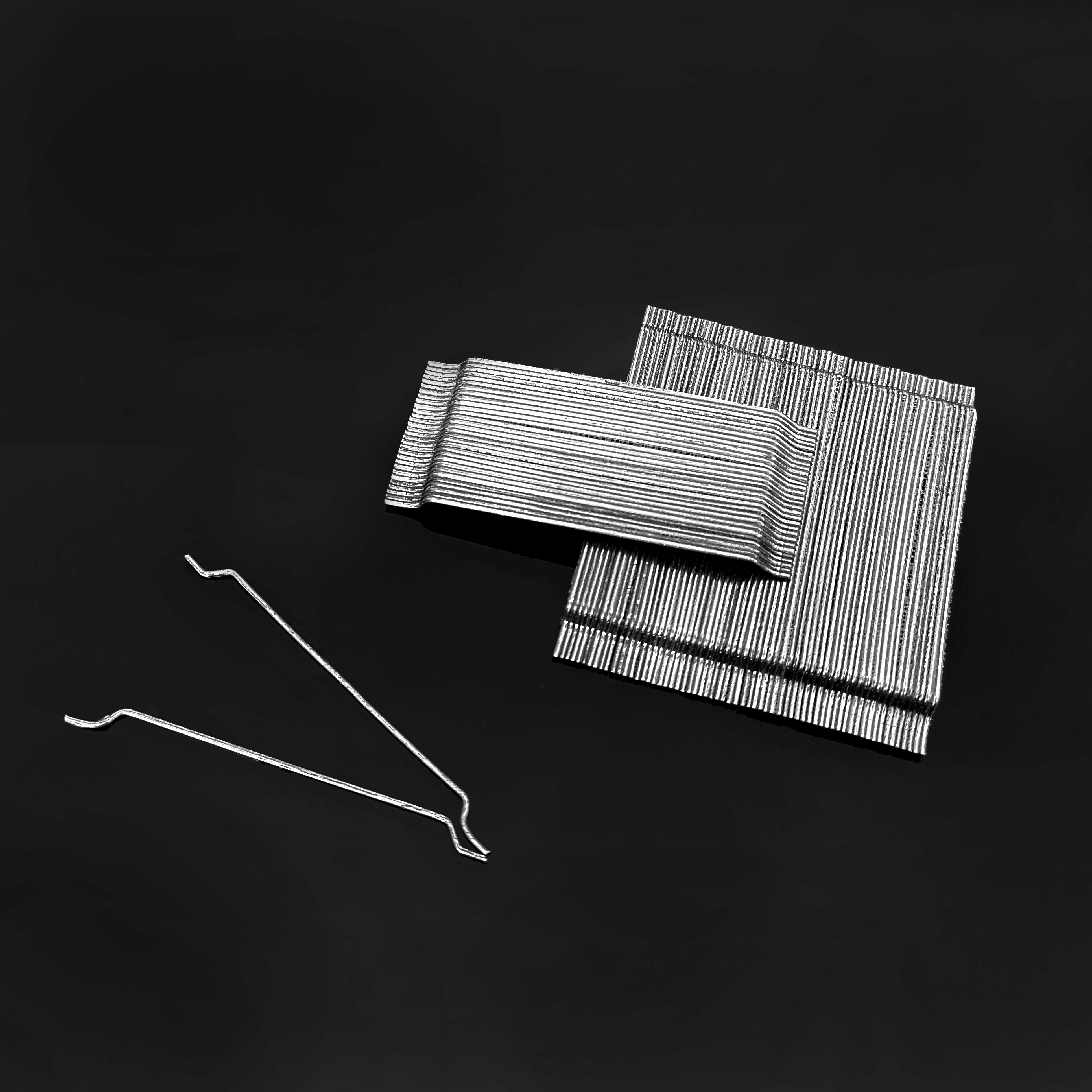

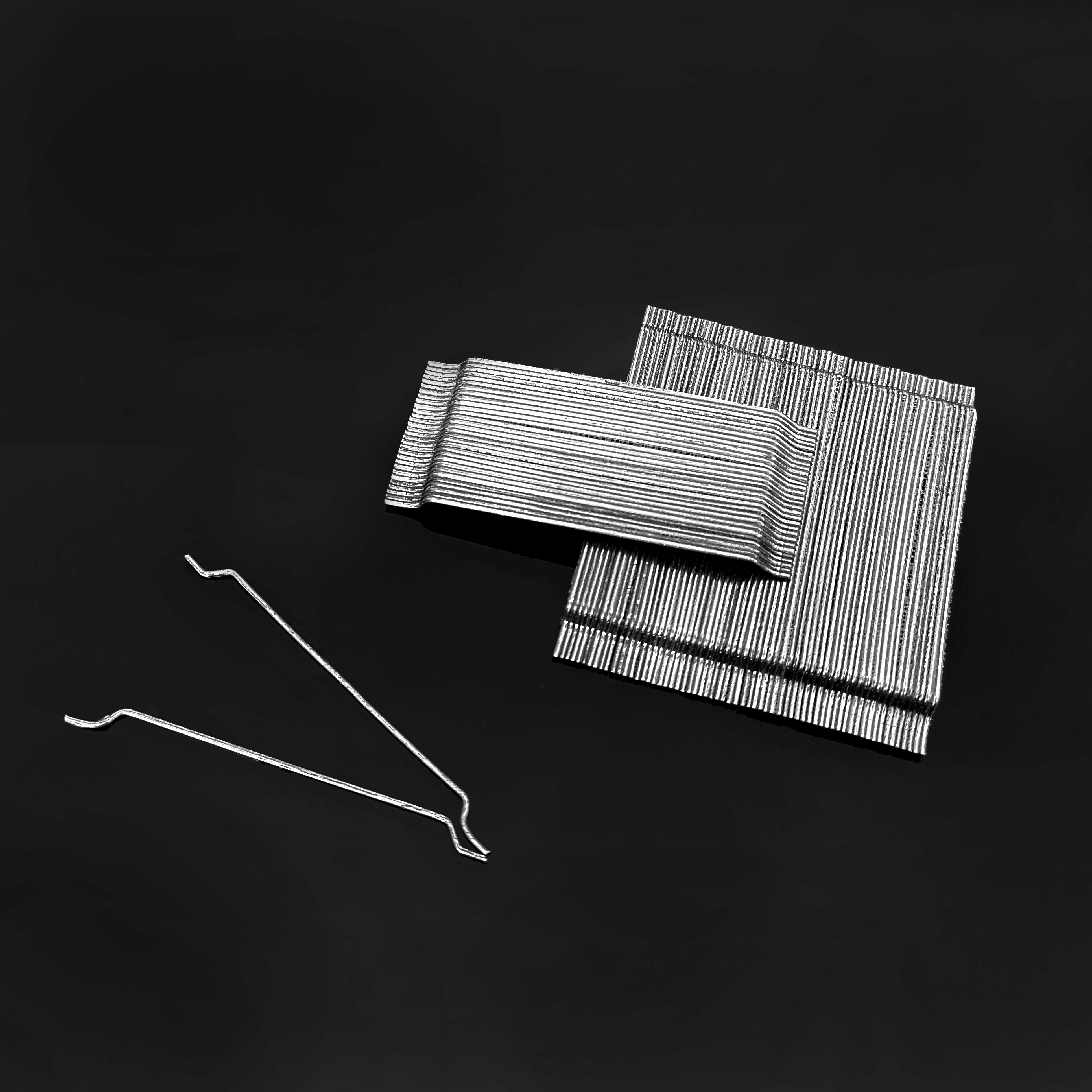

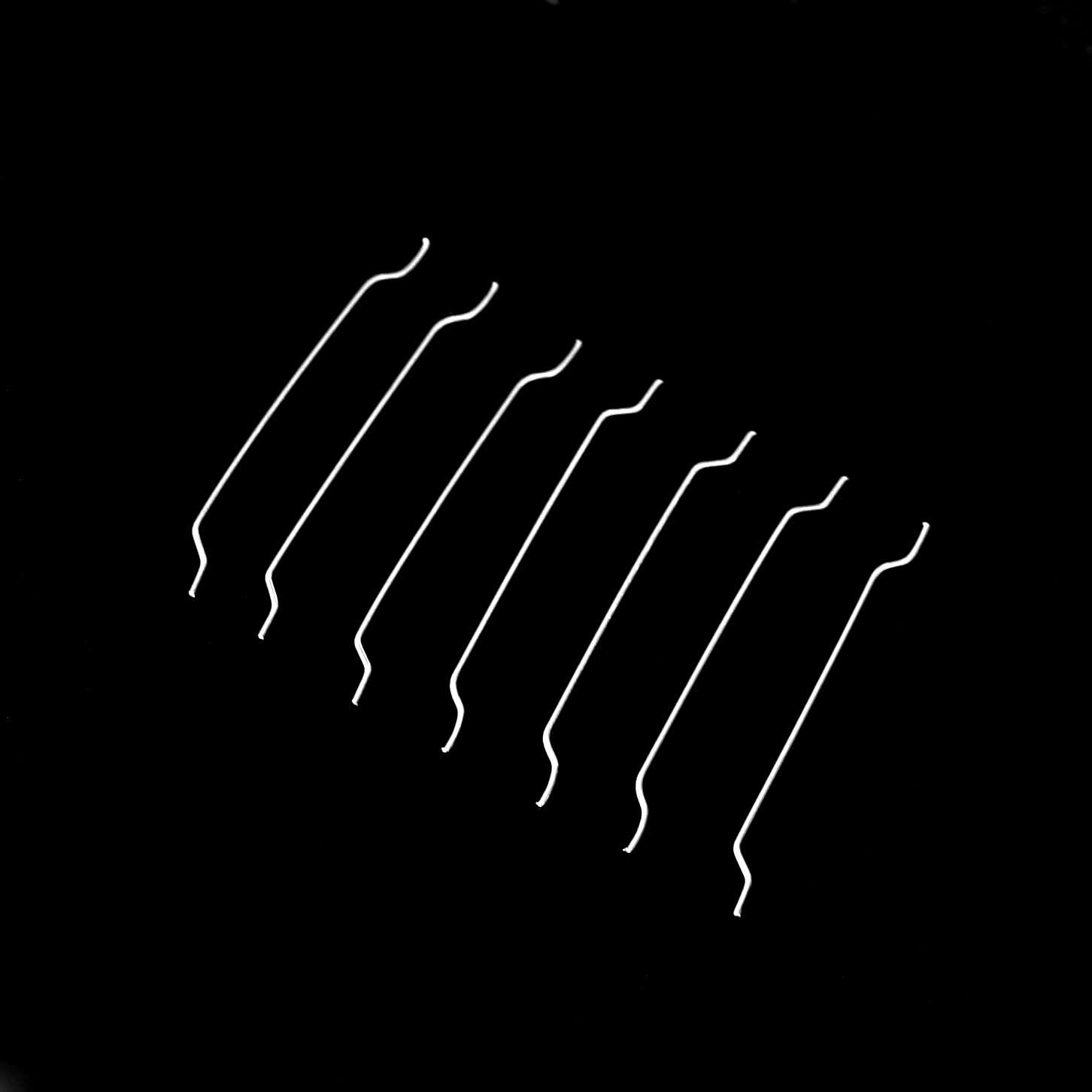

9 mm diameter steel fiber

A Company You Can Trust:Tangshan YiAn metal products co., Ltd is a professional manufacturer of steel fiber. We have more than 10 years of experience in this field and have a good reputation in this field. Our products have won praise from customers worldwide.Quality and Safety:We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Our products have attained some certifications.Your Success, Our Glory:Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

| Product name | 9 mm diameter steel fiber |

| Keyword | china steel fiber wire suppliers,9 mm diameter 50 mm steel fiber,crimped steel fiber concrete,saryn steel fiber |

| Place of Origin | China |

| Applicable Industries | rapid transit railway, etc. |

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Philippines,Northern Mariana Islands,Sudan,Timor-Leste,Bermuda,Nigeria,Marshall Islands,Jersey |

FAQ Guide

Let’s continue!

2.Can steel fiber replace traditional reinforcement in concrete?

3.Are there any special handling or safety precautions for using 9 mm diameter steel fiber in concrete?

4.Can 9 mm diameter steel fiber reduce the overall weight of concrete structures?

5.What research has been done to validate the effectiveness of 9 mm diameter steel fiber in concrete applications?

1.What is the typical dosage of steel fiber in concrete mixtures?

The typical dosage of steel fiber in concrete mixtures ranges from 20 to 40 kg/m3 (33 to 66 lb/yd3). However, the exact dosage may vary depending on the specific application and desired properties of the concrete. It is important to consult with a structural engineer or concrete supplier to determine the appropriate dosage for a particular project.

2.Can steel fiber replace traditional reinforcement in concrete?

Steel fiber can be used as a replacement for traditional reinforcement in certain applications, but it is not a complete replacement. Traditional reinforcement, such as steel bars or mesh, is still necessary for structural integrity and to resist tensile forces in concrete. Steel fiber can be added to concrete to improve its strength, durability, and crack resistance, but it cannot completely replace traditional reinforcement. Additionally, the use of steel fiber in concrete requires careful design and testing to ensure its effectiveness and compatibility with the specific project requirements.

3.Are there any special handling or safety precautions for using 9 mm diameter steel fiber in concrete?

Yes, there are several special handling and safety precautions that should be followed when using steel fiber in concrete:

1. Personal Protective Equipment (PPE): Workers should wear appropriate PPE, such as gloves, safety glasses, and protective clothing, when handling steel fibers to prevent cuts and abrasions.

2. Proper Storage: Steel fibers should be stored in a dry and well-ventilated area to prevent rusting. They should also be kept away from sources of moisture and heat.

3. Mixing: When mixing steel fibers into concrete, it is important to follow the manufacturer's instructions and use the correct amount of fibers. Overmixing can cause the fibers to clump together, while undermixing can result in uneven distribution of fibers in the concrete.

4. Handling: Steel fibers should be handled carefully to avoid bending or damaging them. They should not be dropped or thrown into the concrete mix.

5. Placement: During concrete placement, workers should avoid stepping on or walking through the steel fiber-reinforced concrete. This can cause the fibers to shift and result in uneven distribution.

4.Can 9 mm diameter steel fiber reduce the overall weight of concrete structures?

Yes, steel fiber can reduce the overall weight of concrete structures. This is because steel fibers are lightweight and can be added to the concrete mix in small quantities, reducing the amount of traditional reinforcement needed. This results in a lighter and more efficient concrete structure. Additionally, steel fibers can also improve the strength and durability of the concrete, allowing for thinner and lighter sections to be used. This can lead to cost savings in materials and transportation, as well as reduced environmental impact.

5.What research has been done to validate the effectiveness of 9 mm diameter steel fiber in concrete applications?

There have been numerous studies and research conducted to validate the effectiveness of steel fiber in concrete applications. Some of the key findings and conclusions from these studies are:

1. Increased Tensile Strength: Steel fibers have been found to significantly increase the tensile strength of concrete. This is due to the fact that the fibers act as reinforcement and help to distribute the load more evenly, reducing the risk of cracking and increasing the overall strength of the concrete.

2. Improved Durability: The addition of steel fibers has been shown to improve the durability of concrete by reducing the risk of cracking and increasing resistance to impact, abrasion, and fatigue. This is particularly beneficial in high-stress applications such as industrial floors and pavements.

3. Enhanced Flexural Strength: Studies have shown that the addition of steel fibers can improve the flexural strength of concrete, making it more resistant to bending and increasing its load-carrying capacity. This is especially important in applications where the concrete is subjected to heavy loads or dynamic forces.

4. Crack Control: Steel fibers have been found to be effective in controlling the formation and propagation of cracks in concrete. This is due to their ability to bridge small cracks and prevent them from growing, thereby improving the overall durability and longevity of the concrete.

5. Reduced Shrinkage: The use of steel fibers has been shown to reduce the shrinkage of concrete, which is a common problem in traditional concrete mixes. This is because the fibers help to hold the concrete together and prevent it from shrinking as it cures.

6. Cost-Effective: Several studies have compared the cost-effectiveness of using steel fibers in concrete versus traditional reinforcement methods such as rebar. The results have shown that in many cases, steel fibers can be a more cost-effective option, especially in applications where high-strength and durability are required.

Overall, the research conducted on the effectiveness of steel fiber in concrete applications has consistently shown that it can provide significant benefits in terms of strength, durability, crack control, and cost-effectiveness. As a result, steel fiber is now widely used in a variety of concrete applications, including industrial floors, pavements, precast elements, and shotcrete.

Tag:copperized steel fiber,steel fiber i95