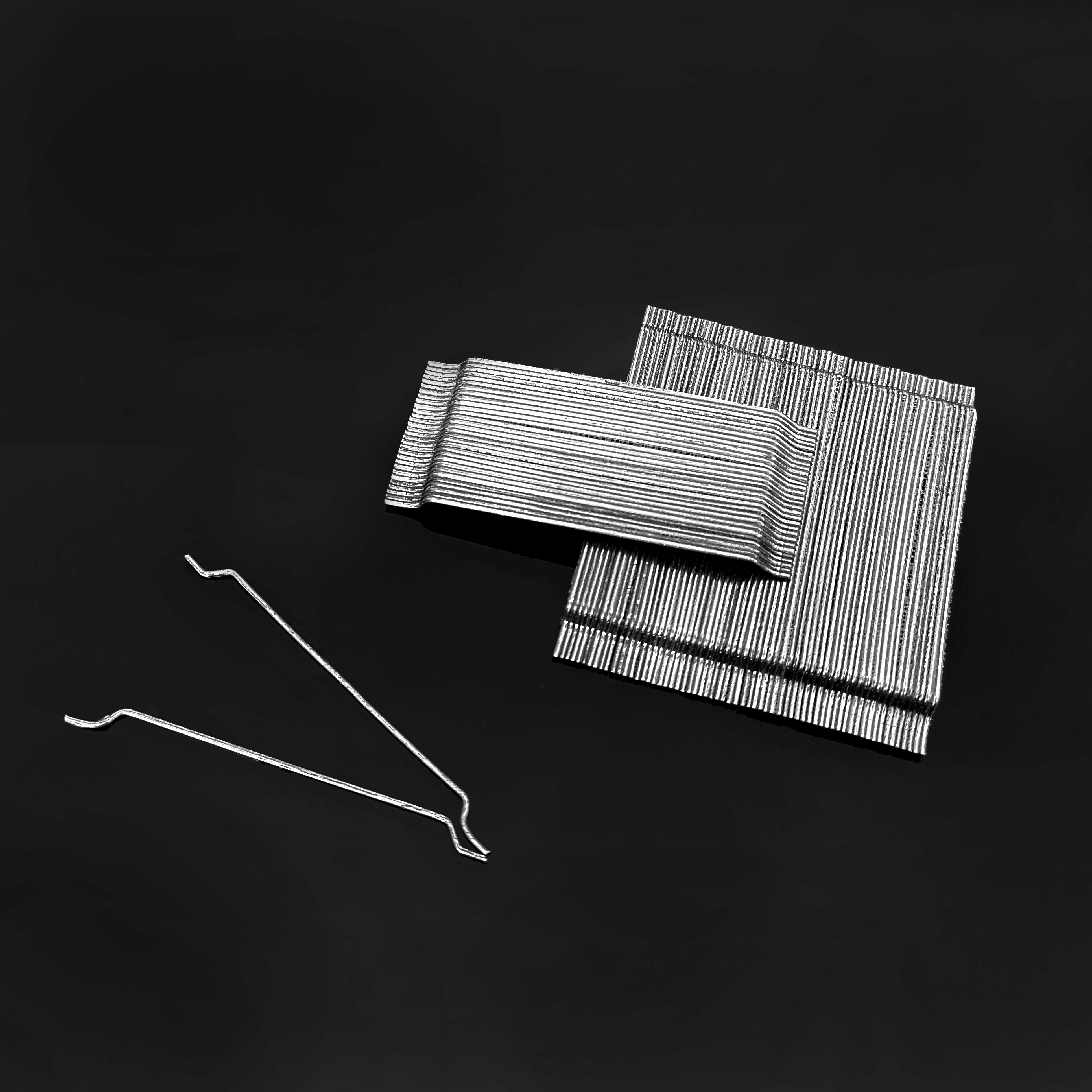

9 mm diameter 50 mm steel fiber

Tangshan YiAn metal products co., Ltd. locates in tangshan city, focusing on production of cold drawn steel wire steel fiber, loose hooked end steel fiber, glued steel fiber, stainless steel fiber, copper coated steel fiber & shear steel fibers, and our products has passed ISO9001 and CE certificate.

Our fiber are widely used in Concrete reinforcement/Precast element And we have sold our fiber to more than 20 counties.

| Product name | 9 mm diameter 50 mm steel fiber |

| Keyword | high strength steel fiber,high strength micro steel fiber,glued steel fiber manufacturers,hic steel fiber |

| Place of Origin | China |

| Applicable Industries | Precast element, etc. |

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Belgium,Wallis and Futuna,Benin,Tuvalu,Sudan,France,Singapore,Lebanon |

FAQ Guide

Let’s continue!

2.How does 9 mm diameter 50 mm steel fiber affect the shrinkage of concrete?

3.Can steel fiber improve the flexural strength of concrete beams?

4.Does steel fiber help prevent cracking in concrete?

5.What is the difference between hooked-end and straight 9 mm diameter 50 mm steel fibers?

1.Can steel fiber replace traditional reinforcement in concrete?

Steel fiber can be used as a replacement for traditional reinforcement in certain applications, but it is not a complete replacement. Traditional reinforcement, such as steel bars or mesh, is still necessary for structural integrity and to resist tensile forces in concrete. Steel fiber can be added to concrete to improve its strength, durability, and crack resistance, but it cannot completely replace traditional reinforcement. Additionally, the use of steel fiber in concrete requires careful design and testing to ensure its effectiveness and compatibility with the specific project requirements.

2.How does 9 mm diameter 50 mm steel fiber affect the shrinkage of concrete?

Steel fibers can have both positive and negative effects on the shrinkage of concrete.

Positive effects:

1. Reduced plastic shrinkage: Steel fibers can help to reduce plastic shrinkage in concrete by providing additional reinforcement and reducing the formation of microcracks. This is especially beneficial in hot and dry weather conditions where plastic shrinkage is more likely to occur.

2. Reduced drying shrinkage: The addition of steel fibers can also help to reduce drying shrinkage in concrete by providing additional restraint and reducing the overall volume change.

3. Improved crack resistance: Steel fibers can improve the crack resistance of concrete by bridging cracks and distributing stress more evenly throughout the concrete matrix. This can help to prevent the formation of large cracks and reduce the overall shrinkage of the concrete.

Negative effects:

1. Increased autogenous shrinkage: Autogenous shrinkage is the self-desiccation of concrete due to the chemical reaction between cement and water. The addition of steel fibers can increase the rate of this reaction, leading to increased autogenous shrinkage and potential cracking.

2. Increased creep: Creep is the gradual deformation of concrete under sustained load. The addition of steel fibers can increase the creep of concrete, which can lead to increased shrinkage over time.

3. Increased risk of corrosion: If the steel fibers are not properly coated or protected, they can be susceptible to corrosion. This can lead to expansion and cracking of the concrete, increasing its overall shrinkage.

Overall, the effect of steel fibers on the shrinkage of concrete will depend on various factors such as the type and dosage of fibers, the mix design, and environmental conditions. Proper selection and placement of steel fibers can help to minimize any negative effects and improve the overall performance of the concrete.

3.Can steel fiber improve the flexural strength of concrete beams?

Yes, steel fiber can improve the flexural strength of concrete beams. Steel fibers are added to concrete to increase its tensile strength and improve its resistance to cracking and failure under bending or flexural loads. The addition of steel fibers can increase the flexural strength of concrete beams by up to 20-30%. This is because the steel fibers act as reinforcement, distributing the load more evenly and preventing cracks from propagating. Additionally, steel fibers can also improve the ductility and toughness of concrete, making it more resistant to sudden impacts or dynamic loads.

4.Does steel fiber help prevent cracking in concrete?

Yes, steel fiber can help prevent cracking in concrete. Steel fibers are added to concrete to improve its tensile strength and ductility, making it less prone to cracking. The fibers act as reinforcement, distributing stress and preventing cracks from forming. They also help to hold the concrete together if cracks do occur, reducing the likelihood of further damage. Additionally, steel fibers can improve the overall durability and longevity of concrete structures.

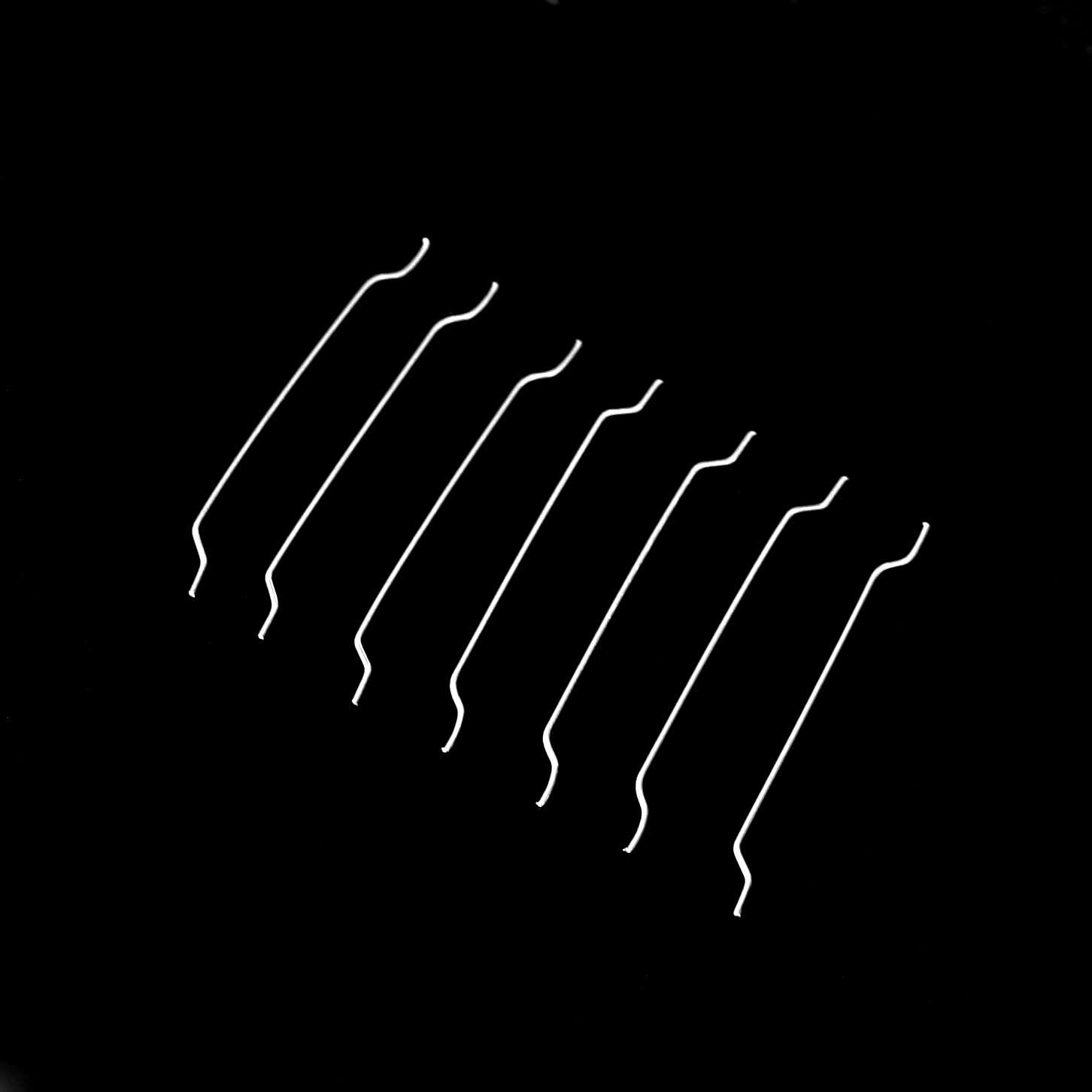

5.What is the difference between hooked-end and straight 9 mm diameter 50 mm steel fibers?

Hooked-end and straight steel fibers are both types of reinforcement used in concrete to improve its strength and durability. The main difference between the two is their shape and how they are anchored in the concrete.

1. Shape: Hooked-end steel fibers have a hook or bend at one or both ends, while straight steel fibers are completely straight.

2. Anchorage: Hooked-end steel fibers are designed to be anchored in the concrete by the hooked ends, which provide better bonding and resistance to pull-out forces. Straight steel fibers rely on their length and surface area to provide anchorage in the concrete.

3. Distribution: Hooked-end steel fibers tend to distribute more evenly throughout the concrete due to their shape and anchorage, while straight steel fibers may clump together and create areas of higher concentration.

4. Reinforcement: Hooked-end steel fibers are more effective in reinforcing concrete in all directions, including tension, compression, and shear, due to their anchorage and distribution. Straight steel fibers are more effective in reinforcing concrete in tension, but may not be as effective in compression and shear.

5. Applications: Hooked-end steel fibers are commonly used in industrial and heavy-duty applications, such as industrial floors, pavements, and precast elements. Straight steel fibers are often used in residential and light commercial applications, such as slabs, driveways, and sidewalks.

In summary, the main difference between hooked-end and straight steel fibers is their shape and anchorage, which affects their distribution and effectiveness in reinforcing concrete. The choice between the two types of fibers depends on the specific application and the desired level of reinforcement.

Tag:hook end steel fiber,steel fiber reinforced concrete