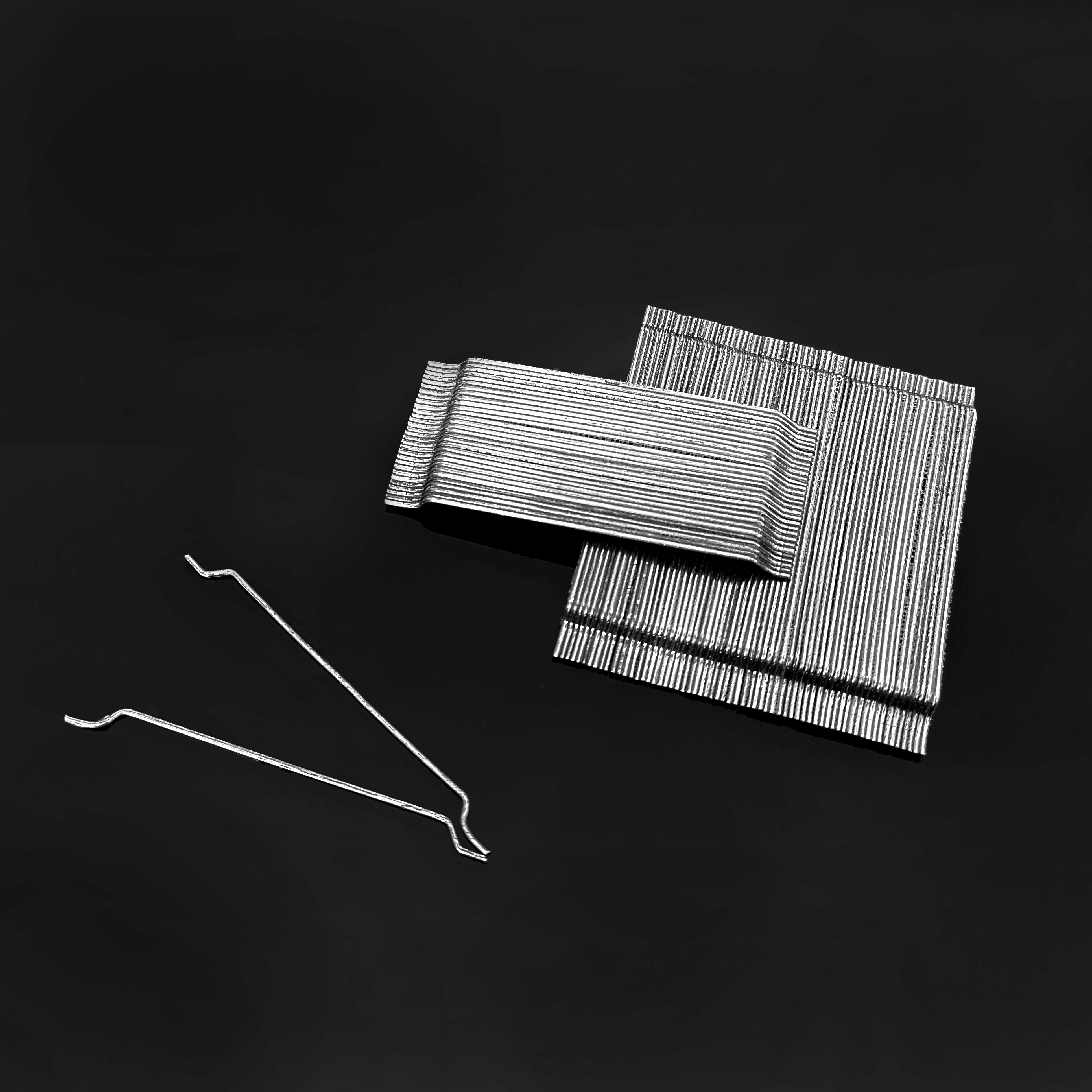

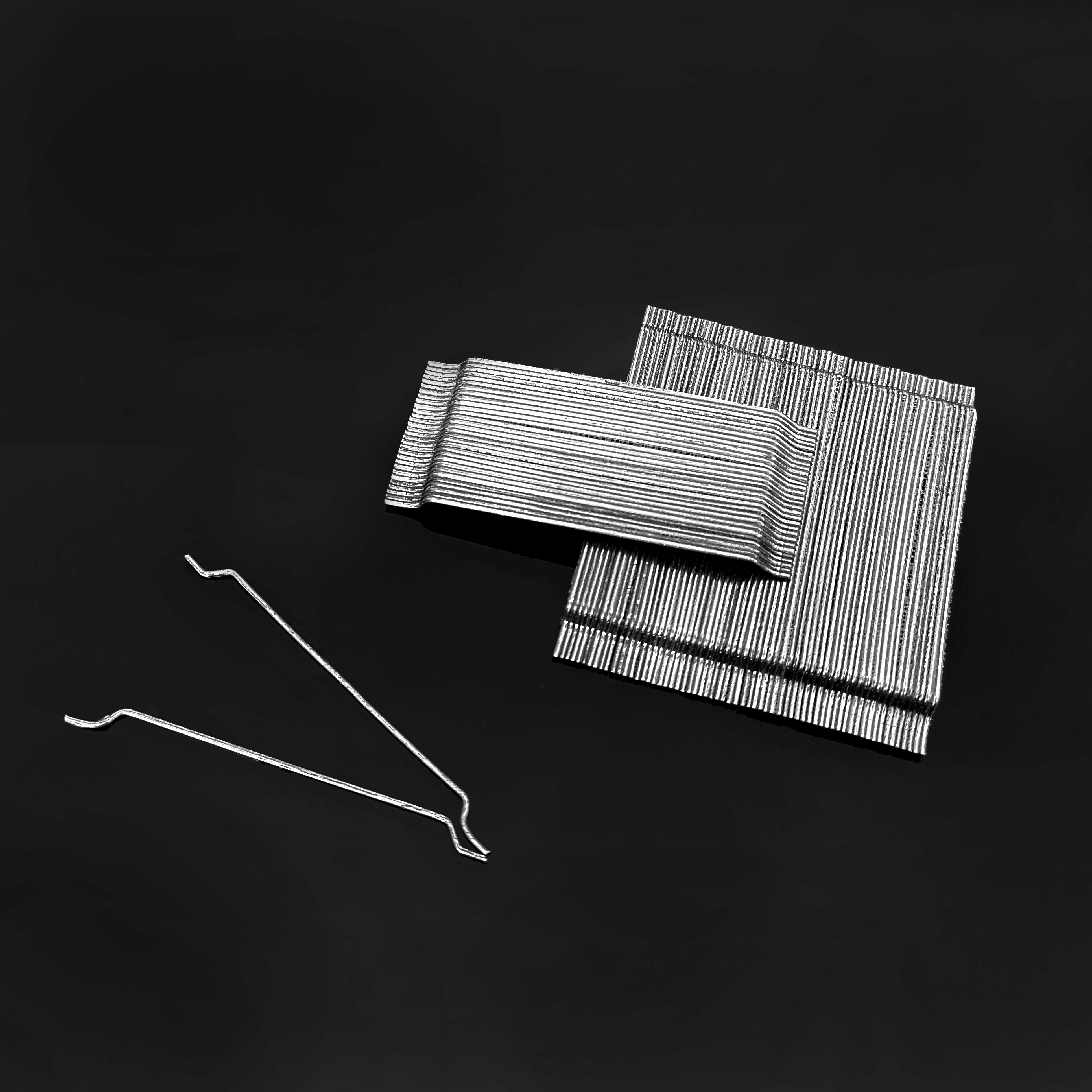

steel fiber density

A Company You Can Trust:Tangshan YiAn metal products co., Ltd is a professional manufacturer of steel fiber. We have more than 10 years of experience in this field and have a good reputation in this field. Our products have won praise from customers worldwide.Quality and Safety:We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Our products have attained some certifications.Your Success, Our Glory:Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

| Product name | steel fiber density |

| Keyword | chroma steel fiber,warframe steel fiber,steel fiber concrete,china steel fiber wires |

| Place of Origin | China |

| Applicable Industries | rapid transit railway, etc. |

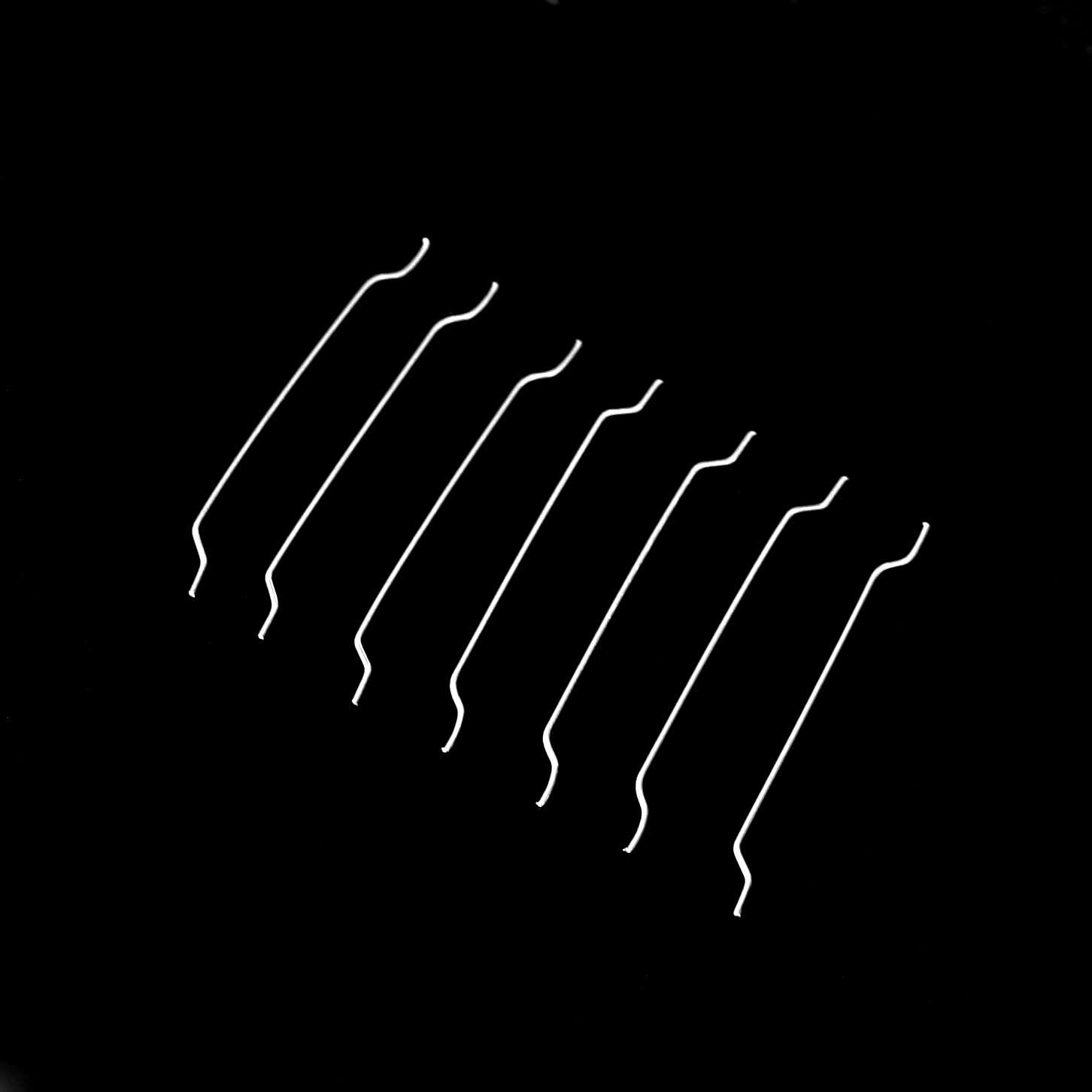

| Product Description | Steel fiber is a concrete reinforcement material, which is a slender fiber made of high-strength steel wire. These wires can be straight, corrugated or zigzag and can be customized and designed as needed. These fibers are added to concrete to effectively enhance its tensile strength, durability and crack resistance. |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Saint Vincent and the Grenadines,Brunei,Rwanda,Tuvalu,Honduras,United States of America,Argentina,Bermuda,Iran |

| Certificate | ISO9001 ,CE |

| Material | Stainless steel,Steel,Carbon Steel,low carbon steel wire |

FAQ Guide

Let’s continue!

2.Is steel fiber suitable for use in high-stress applications?

3.Can steel fiber improve the flexural strength of concrete beams?

4.How does the presence of steel fiber affect the workability of concrete?

5.Can steel fiber density reduce the risk of spalling in concrete structures?

1.Do certain types of steel fiber work better in specific climates or environments?

Yes, certain types of steel fiber may work better in specific climates or environments. For example, stainless steel fibers are more resistant to corrosion and may be better suited for use in humid or coastal environments. On the other hand, galvanized steel fibers may be more suitable for use in areas with high levels of moisture or exposure to chemicals. Additionally, the shape and size of the steel fibers can also affect their performance in different environments. For example, hooked or crimped fibers may be more effective in resisting cracking in cold climates, while straight fibers may be better suited for use in hot and dry environments. Ultimately, the selection of the most suitable type of steel fiber will depend on the specific conditions and requirements of the project.

2.Is steel fiber suitable for use in high-stress applications?

Yes, steel fiber is suitable for use in high-stress applications. Steel fibers are known for their high tensile strength and durability, making them ideal for use in applications where high stress and heavy loads are present. They are commonly used in reinforced concrete structures, such as bridges, tunnels, and industrial floors, to improve their strength and resistance to cracking and fatigue. Steel fibers are also used in shotcrete and precast concrete applications, as well as in soil stabilization and reinforcement projects. Overall, steel fibers are a reliable and effective reinforcement material for high-stress applications.

3.Can steel fiber improve the flexural strength of concrete beams?

Yes, steel fiber can improve the flexural strength of concrete beams. Steel fibers are added to concrete to increase its tensile strength and improve its resistance to cracking and failure under bending or flexural loads. The addition of steel fibers can increase the flexural strength of concrete beams by up to 20-30%. This is because the steel fibers act as reinforcement, distributing the load more evenly and preventing cracks from propagating. Additionally, steel fibers can also improve the ductility and toughness of concrete, making it more resistant to sudden impacts or dynamic loads.

4.How does the presence of steel fiber affect the workability of concrete?

The presence of steel fiber in concrete can significantly affect its workability. Workability refers to the ease with which concrete can be mixed, placed, compacted, and finished without segregation or bleeding.

The addition of steel fibers to concrete can increase its viscosity and make it more difficult to mix and place. This is because the fibers tend to clump together and can create a sticky and lumpy mixture. As a result, more water may be needed to achieve the desired consistency, which can lead to a decrease in the strength and durability of the concrete.

Moreover, the presence of steel fibers can also make the concrete more difficult to compact. The fibers can get in the way of the compaction process, leading to poor consolidation and an increase in the number of voids in the concrete. This can result in a decrease in the strength and durability of the concrete.

On the other hand, the addition of steel fibers can also improve the workability of concrete in certain cases. For example, in shotcrete applications, the fibers can help to reduce rebound and improve the workability of the concrete. Additionally, the use of certain types of fibers, such as hooked-end fibers, can help to improve the flow and workability of the concrete.

In summary, the presence of steel fibers in concrete can have both positive and negative effects on its workability. It is important to carefully consider the type and amount of fibers to be added to the concrete to ensure that the desired workability and strength are achieved.

5.Can steel fiber density reduce the risk of spalling in concrete structures?

Yes, steel fiber can reduce the risk of spalling in concrete structures. Steel fibers are added to concrete mixtures to improve its strength, durability, and resistance to cracking. When used in high-stress areas, such as in concrete structures, steel fibers can help prevent spalling by providing additional reinforcement and reducing the formation of cracks. This helps to maintain the integrity of the concrete and prevent water and other harmful substances from penetrating and causing spalling. Additionally, steel fibers can also improve the bond between the concrete and any reinforcing steel, further reducing the risk of spalling.