Powering Infrastructure: The Benefits of Using Glued Steel Fiber in Roads and Bridges

Powering Infrastructure: The Benefits of Using Glued Steel Fiber in Roads and Bridges

When it comes to constructing roads and bridges, the strength and durability of the materials used are crucial. Traditional construction methods typically rely on reinforced concrete, which can be prone to cracking and deteriorating over time. However, there is a newer material that is gaining popularity in the construction industry – glued steel fiber.

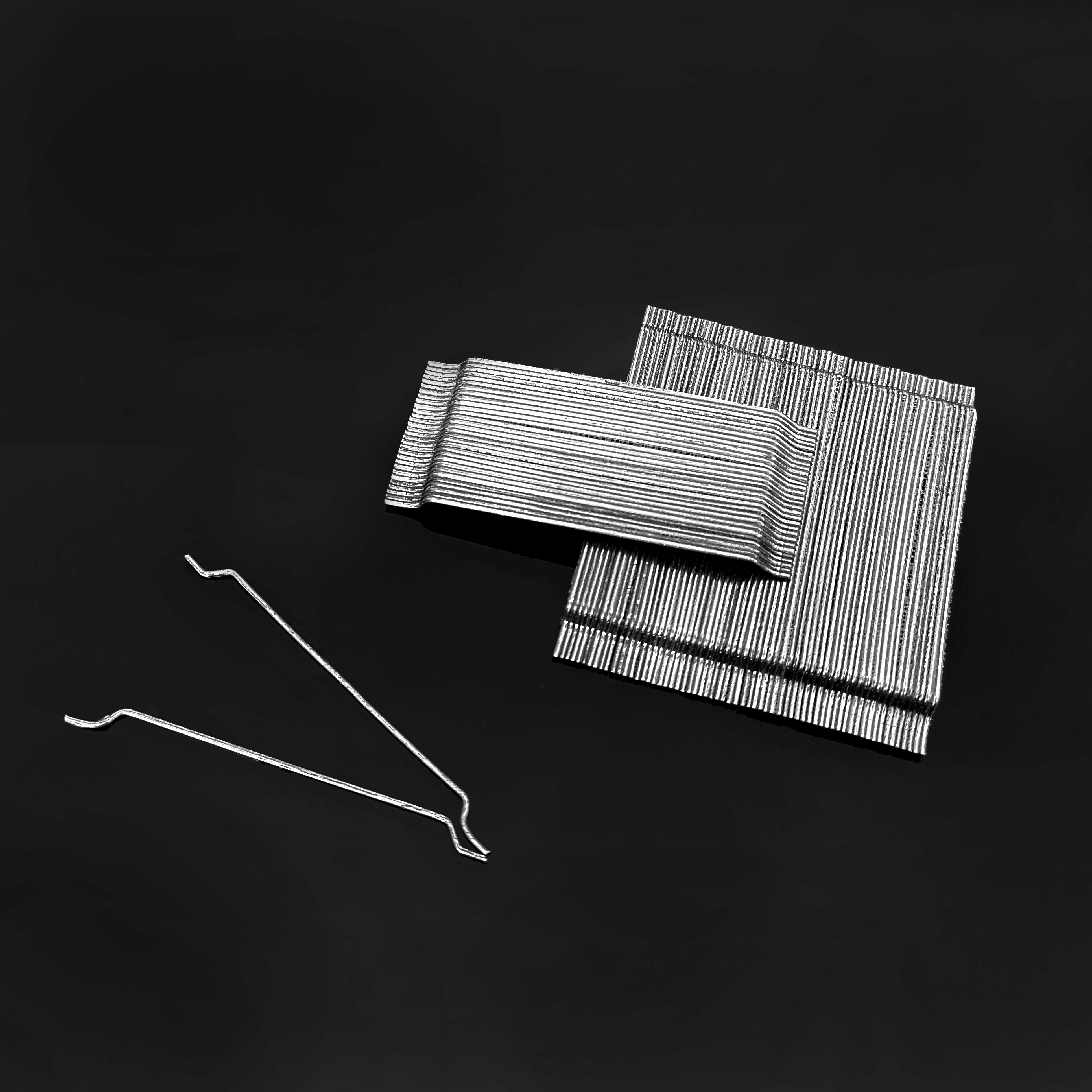

Glued steel fiber, also known as steel fiber reinforced concrete, is a composite material made up of concrete and steel fibers that are coated with a bonding agent. Unlike traditional concrete, which relies solely on steel bars or meshes for reinforcement, glued steel fiber distributes the strength and durability throughout the entire structure.

One of the key benefits of using glued steel fiber in roads and bridges is its ability to increase the tensile strength of concrete. This means that the material can withstand higher levels of stress without cracking or breaking. In fact, research has shown that glued steel fiber can improve the flexural and tensile strength of concrete by up to 30%.

The improved strength of glued steel fiber also means that it can resist heavy traffic loads better than traditional concrete. This is especially beneficial for roads and bridges, which experience high levels of wear and tear from constant use by vehicles. With glued steel fiber, these structures can last longer and require fewer repairs, saving time and money in the long run.

Another advantage of using glued steel fiber is its ability to prevent cracking in concrete. Due to its enhanced tensile strength, the material can withstand shrinkage and temperature changes that often cause cracks in traditional concrete. This is particularly beneficial in colder climates where freeze-thaw cycles can cause significant damage to roads and bridges.

Additionally, glued steel fiber has been proven to increase the lifespan of roads and bridges. A study by the Institute for Transportation at Iowa State University found that incorporating steel fibers into concrete can extend the service life of pavements by up to 50% compared to traditional concrete. This is due to the material's ability to withstand heavy traffic, prevent cracking, and resist chemical deterioration.

In terms of cost-effectiveness, glued steel fiber may be a more viable option than traditional reinforced concrete. While the upfront cost of glued steel fiber may be slightly higher, the longer lifespan and decreased need for repairs can result in overall cost savings. Plus, with the use of steel fibers, less concrete is needed, reducing the overall cost of construction.

Moreover, glued steel fiber is a sustainable option. It can be made with recycled steel, reducing the environmental impact of construction projects. Additionally, the longer lifespan of roads and bridges means less material needs to be replaced, resulting in less waste and lower carbon emissions.

Glued steel fiber is also highly versatile and can be customized for different construction needs. Different types of fibers can be used, such as hooked-end fibers for high-impact areas or crimped fibers for improved bonding with the concrete. This allows for more specialized and durable structures to be built, catering to the specific demands of each project.

The use of glued steel fiber in roads and bridges has numerous benefits, including increased strength and durability, crack prevention, longer lifespan, cost-effectiveness, sustainability, and versatility. As more and more research is conducted on this material, it is expected to become an increasingly popular choice in infrastructure projects.

The Secret to Superior Construction: Discover the Magic of Glued Steel Fiber

Construction is an essential part of any developing society, providing necessary infrastructure, housing and commercial buildings. It is therefore vital that construction materials and techniques are continuously improved upon to ensure long-lasting results. One such innovation that has revolutionized the construction industry is the use of glued steel fibers in concrete.

Glued steel fibers are thin filaments of steel, typically ranging from 25 to 60mm in length, that are mixed with concrete during the production process. These fibers provide additional strength and durability to the concrete, making it suitable for a variety of high-performance applications.

The use of steel fibers in construction dates back to the 1960s when industrial waste materials such as shredded tires, plastic, and glass were used to reinforce concrete. However, it was not until the 1980s that glued steel fibers emerged as a superior choice for enhancing the performance of concrete. The magic of glued steel fibers lies in their unique properties, which make them an ideal reinforcement material for concrete structures.

Enhanced Strength and Durability

The primary advantage of using glued steel fibers in concrete is the significant improvement in strength and durability. The fibers bind to the concrete matrix, creating a sturdy and interconnected network that greatly increases the tensile and flexural strength of the material. This results in a more robust and durable concrete that can withstand heavy loads and extreme weather conditions.

The addition of steel fibers also increases the fatigue resistance of the concrete, making it less susceptible to cracking and damage over time. This is particularly beneficial in high-traffic areas, such as roads and bridges, where heavy vehicles and constant stress can cause premature wear and tear.

Improved Crack Control

One of the biggest challenges in concrete construction is controlling cracking. Traditional reinforcement methods, such as using rebar, are effective in preventing cracking, but they are not foolproof. Glued steel fibers, on the other hand, greatly improve crack control in concrete.

When combined with concrete, steel fibers form a three-dimensional framework that effectively holds the concrete together, preventing cracks from forming and expanding. This is especially useful in concrete slabs, where shrinkage and temperature changes often lead to cracking. With glued steel fibers, the concrete is better able to withstand these forces, resulting in a more durable and long-lasting structure.

Versatility

Another significant advantage of using glued steel fibers is their versatility when it comes to applications. Unlike traditional reinforcement methods, which are usually limited to specific shapes and sizes, steel fibers are easily incorporated into various concrete mixes and forms.

This makes them suitable for a wide range of construction projects, including roads, pavements, industrial floors, and precast elements. In addition, the fibers can be added to both wet and dry concrete mixes, making them a convenient and efficient reinforcement option for contractors.

Cost-Effective

The use of glued steel fibers in concrete can also result in cost savings for construction projects. Since the fibers eliminate the need for traditional reinforcement methods, such as rebar or mesh, their use can reduce construction time and labor costs. Additionally, the increased strength and durability of the concrete may result in lower maintenance and repair costs in the long run.

Eco-Friendly Option

The environmentally-conscious construction industry is constantly seeking ways to reduce its carbon footprint and minimize waste. The use of glued steel fibers offers a more sustainable option as it diverts industrial waste, such as steel mill by-products, from landfills and repurposes them for construction.

Furthermore, since the fibers themselves are recyclable, they can be reused in future construction projects, reducing the need for new resources.

Glued steel fibers have undoubtedly transformed the construction industry, providing a superior alternative to traditional reinforcement methods. Their unique properties not only improve the strength and durability of concrete but also offer cost savings, versatility, and eco-friendliness, making them a popular choice among contractors and engineers.

As the construction industry continues to evolve, the use of glued steel fibers is expected to become even more widespread. With ongoing research and development, the magic of glued steel fibers will likely unlock even more benefits and possibilities for construction projects in the future. It is indeed the secret to superior construction – offering the perfect combination of strength, durability, and sustainability.